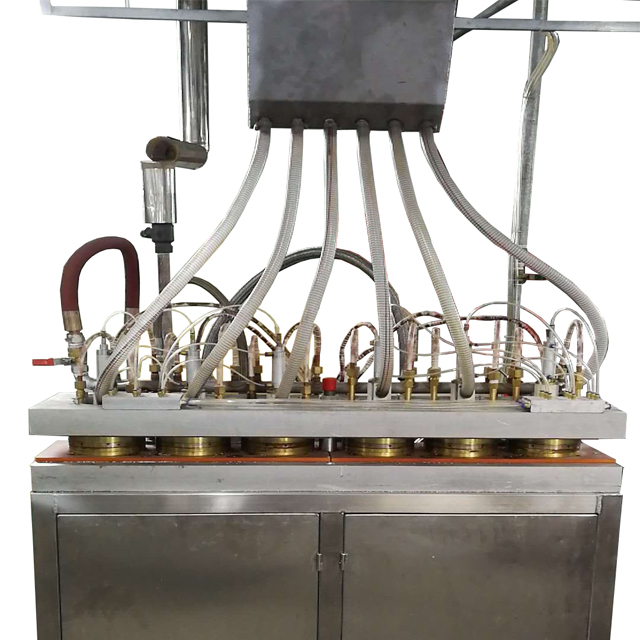

Special Design for Plastic Injection Molding - High Quality EPS Expandable Styrofoam Packaging Boxes Vacuum Forming Machine – WELLEPS

Special Design for Plastic Injection Molding - High Quality EPS Expandable Styrofoam Packaging Boxes Vacuum Forming Machine – WELLEPS Detail:

Main advantage:

1. Use servo drive system, the machine can work very stable.

2. Use two side steam and vacuum, machine works more efficiently.

3. With special design ejectors shelf for easy to install the moulds.

Characteristics:

1. Use proportional steam valve for save steam and heat accurately.

2. Can install the filling guns and ejectors on the ground, can save time to install moulds.

3. Special designed hopper can control the material filling more accurately to ensure make good quality products.

4. Use stainless steel oil pipes to keep machine running stable and not leak oil.

5. Lock moulds same as Germany machine, can keep high pressure in the moulds.

6. All pipe and mould plate coated with zinc, to ensure the machine not easy to get rust and long time running with the steam and water.

| Item | PSZS-1412 | PSZS-1816 | PSZS-2018 | ||

| Mould Dimension | mm | 1400*1200 | 1850*1600 | 2000*1800 | |

| Rear window dimensions | mm | 1250*1050 | 1700*1450 | 1750*1650 | |

| Effective forming area | mm | 1200*1000 | 1500*1250 | 1650*1450 | |

| Max Produce Size | mm | 400 | 400 | 400 | |

| Steam | Pipe connect | DN | 100 | 100 | 100 |

| Die connect | DN | 40/6 | 40/8 | 40/8 | |

| Pressure | kg/cm² | <5 | <5 | <5 | |

| Consumption | kg/cycle | 3-12 | 3-15 | 3-18 | |

| Air | Pipe connect | DN | 80/2 | 80/2 | 80/4 |

| Pressure | kg/cm² | <4 | <4 | <4 | |

| Cooling Water | Pipe connect | DN | 80 | 80 | 80 |

| Die connect | DN | 25/2 | 25/3 | 25/3 | |

| Pressure | kg/cm² | <3 | <3 | <3 | |

| temperature | ℃ | 45-55 | 45-55 | 45-55 | |

| Single Vacuum | Motor | KW | 5 | 7.5 | 7.5 |

| Connect | DN | 100 | 100 | 100 | |

| Drain | DN | 40 | 40 | 40 | |

| Dain water | DN | 25 | 25 | 25 | |

| Vacuum Center | Connect | DN | 100 | 100 | 100 |

| Drainage | Drain Outlet | Φ | 159 | 159 | 159 |

| Mould Outlet | DN | 40/3 | 40/4 | 40/4 | |

| Hydralic system | Motor | KW | 7.5 | 11 | 11 |

| Pump | L/min | 31/97 | 31/116 | 31/116 | |

| Lock power | T | 24 | 37 | 46 | |

| Open-close cylinder | mm | 100*2 | 125*2 | 140*2 | |

| Demould cylinder | mm | 50*2 | 50*2 | 50*2 | |

| Hopper | Volume | m³ | 0.3 | 0.4 | 0.4 |

| Motor | KW | 1.5 | 2.2 | 2.2 | |

| Material hole | Pieces | 22 | 44 | 44 | |

| Electric Load | KW | 16.5 | 20.7 | 20.7 | |

| Overall Dimension | mm | 4800*3320*2800 | 4800*3600*3200 | ||

| Weight | kg | 7200 | 8000 | ||

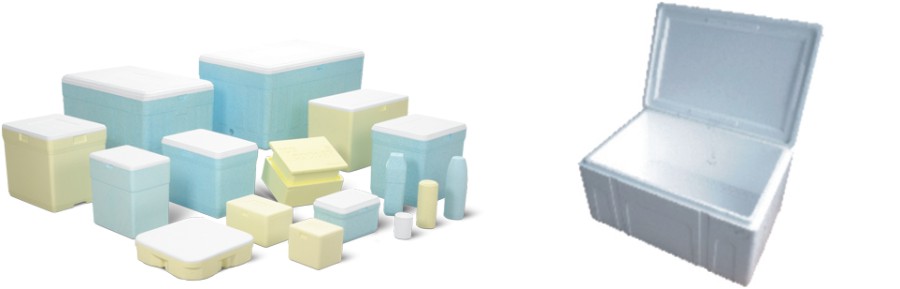

Applications of EPS Box Foam Machine:

EPS foam Machine is widely used to make EPS foam fish box

EPS foam packages for transpotation

EPS ICF blocks for construction building

EPS foam decoration cornice ceilling,etc.

Packaging & Shipping :

Packing: standard exporting package

Shippingport: shanghai/Ningbo

Services:

1. Value clients, guarantee equipment quality and answer clients’ questions anytime and anywhere.

2. Customizing machines according to clients’ inquiry , such as different design, different brand parts, different colors, more function,etc.

3. Engineers go to clients’ factory in time for installation , training and trial production .

4. Lifetime technical service support.

If you are interested in any of our products or would like any support from us about your

factory or any others, please feel free to contact us. We are looking forward to building long

well and friendly business relationships with clients from all over the world.

Product detail pictures:

Related Product Guide:

That has a sound small business credit, great after-sales service and modern production facilities, we've earned an outstanding standing amid our buyers across the earth for Special Design for Plastic Injection Molding - High Quality EPS Expandable Styrofoam Packaging Boxes Vacuum Forming Machine – WELLEPS , The product will supply to all over the world, such as: Malta, Mongolia, Japan, With strong technical strength and advanced production equipment, and SMS people purposefully , qualified, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.