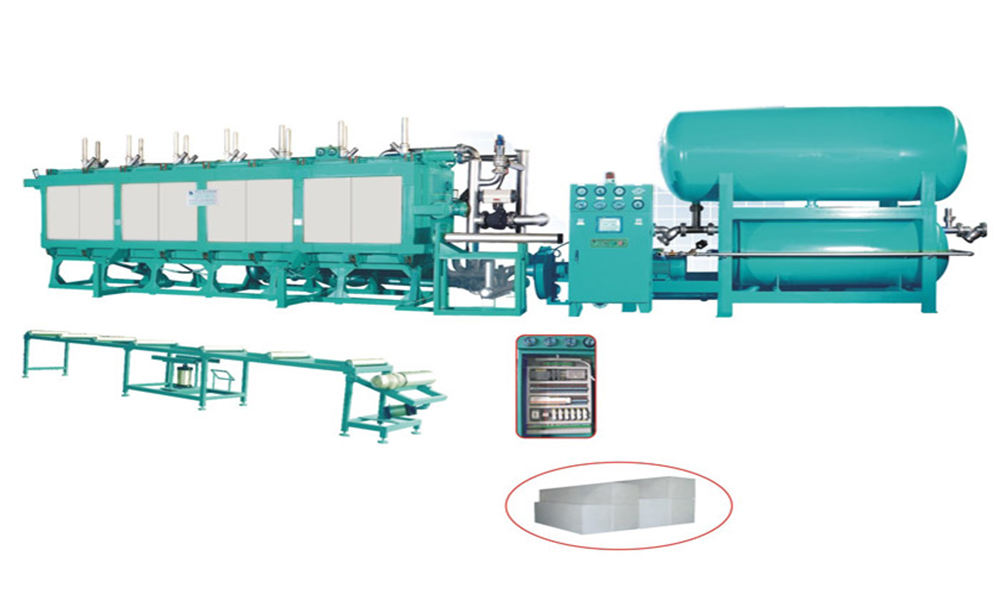

Renewable Design for Etpu Foam Shoe Sole Mould - Automatic EPS Block Molding Machine with air cooling – WELLEPS

Renewable Design for Etpu Foam Shoe Sole Mould - Automatic EPS Block Molding Machine with air cooling – WELLEPS Detail:

Main Features

1. Machine is made of high strength pipe and steel plate, all the steel is under heat treatment, sand blasting, spraying antirust painting, to increasing strength, not rust, to ensure machine operation is stable and long service life.

2. Machine adopts advanced processing technology and better pipe structure design, greatly improving the production efficiency.

3. Machine use unique heating process and efficient vacuum with condensing system, has strong steam penetrating power and energy saving design. Produced blocks have excellent cohesiveness, low moisture content, to ensure every customer’s satisfy.

4. Adopt PLC and touch screen control system, equipped with material level sensor can realize automatic control of feeding, equipped with foam pressure sensor control cooling time automatically.

5. Machine use good quality electrical, pneumatic components, valves and other parts. And the parts with international standard, so customer is easy to find replacement at local.

6. Machine adopts hydraulic pressure station to be the center control system. Use hydraulic open door, ejector de-mould and locking, guarantee the machine running smoothly, stable performance.

Technical Data

| Item | PSB200TF | PSB300TF | PSB400TF | PSB600TF | |

| Mould Cavity Size | mm | 2040*1240*630 | 3060*1240-940*630 | 4080*1240-940*630 | 6100*1240-940*630 |

| Block Size | mm | 2000*1200*600 | 3000*1200-900*600 | 4000*1200-900*630 | 6000*1200-900*600 |

| Steam | ENTRY | DN150 | DN150 | DN150 | DN200 |

| Consumption | 20-30kg/cycle | 30-40kg/cycle | 45-55kg/cycle | 60-70kg/cycle | |

| Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Compressed Air | ENTRY | DN40 | DN40 | DN50 | DN65 |

| Consumption | 1-1.5m³/cycle | 1.5-1.8m³/cycle | 1.8-2m³/cycle | 2-2.3m³/cycle | |

| Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Drainage | Steam vent | φ100mm | φ100mm | φ200mm | φ200mm |

| Blower outlet | φ100mm | φ100mm | φ150mm | φ150mm | |

| Throughpt | 15kg/m3 | 7-12min/cycle | 8-15min/cycle | 8-18min/cycle | 8min/cycle |

| Power | 14.5Kw | 14.5Kw | 18.5Kw | 18.5Kw | |

| Overall Dimension | L*W*H | 4000*2150*2120 | 5030*2270*2120 | 6040*2270*2250 | 8100*2500*3100 |

| Weight | 6000kg | 7500kg | 12000kg | 15000kg | |

| Room Height Required | 6000mm | 6000mm | 6000mm | 6000mm |

Products

Remarks

F is air cooling type, air cooling without vacuum system.

F type products of maximum thickness is 600 mm.

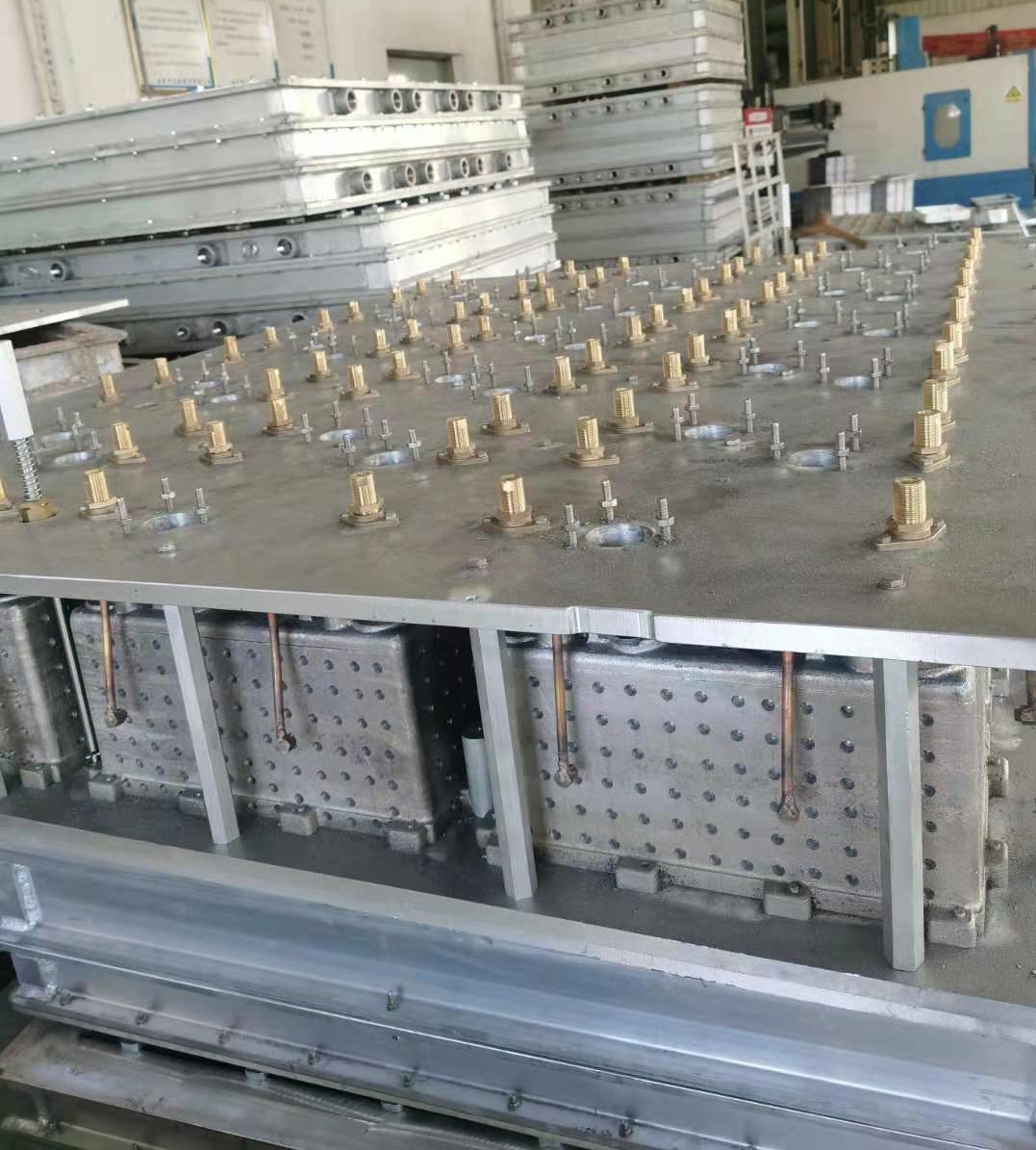

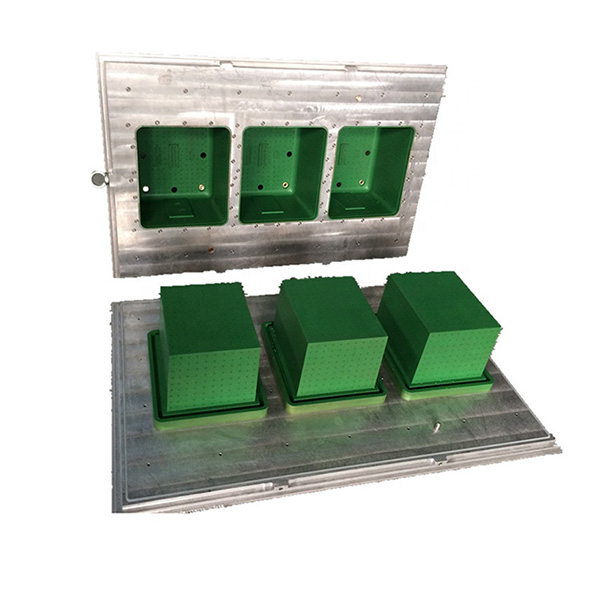

Product detail pictures:

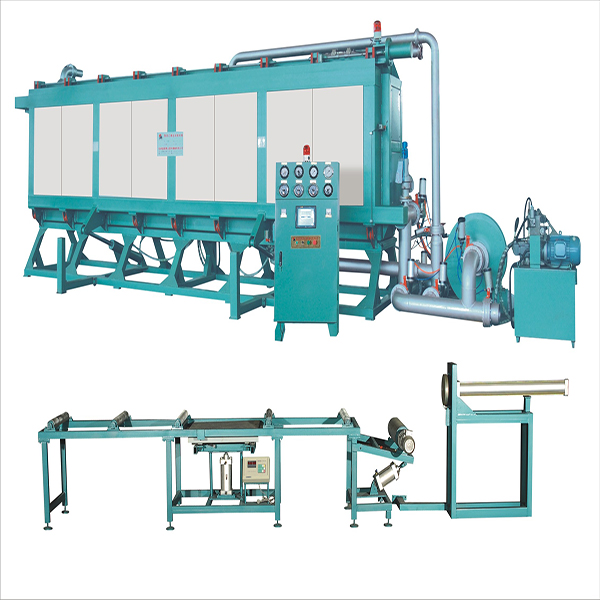

Related Product Guide:

Assume full responsibility to meet all demands of our clients; achieve continuous advancements by promoting the growth of our clients; become the final permanent cooperative partner of clients and maximize the interests of clients for Renewable Design for Etpu Foam Shoe Sole Mould - Automatic EPS Block Molding Machine with air cooling – WELLEPS , The product will supply to all over the world, such as: Puerto Rico, Kazakhstan, El Salvador, Our professional engineering group will always be ready to serve you for consultation and feedback. We are able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to give you the ideal service and goods. For anyone who is thinking about our company and merchandise, please contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Please feel free to get in touch with us for business and we believe we are going to share the top trading practical experience with all our merchants.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!