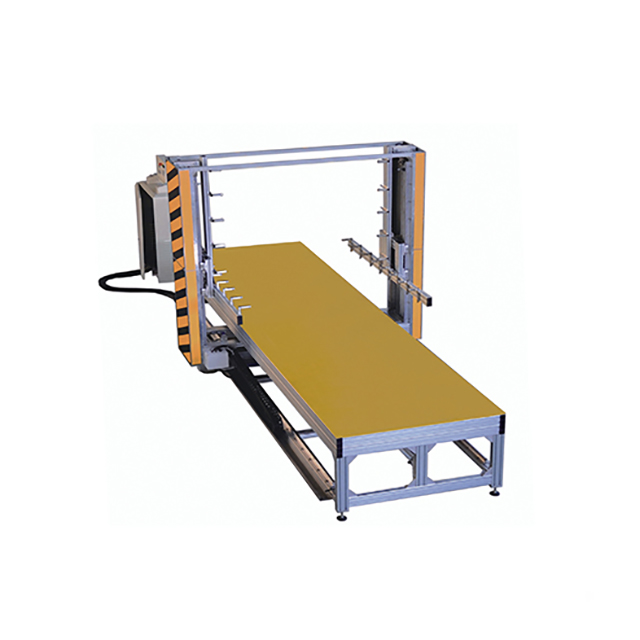

professional factory for Polystyrene Machine - Auto Shape Molding Machine With Vacuum – WELLEPS

professional factory for Polystyrene Machine - Auto Shape Molding Machine With Vacuum – WELLEPS Detail:

Main Features

1.Equipment body use the high strength steel welded together, after the tempering process, sandblasting processing, to ensure the machine have strong structure, not get rust and increase the machine’s working life

2.Equipment adopts Mitsubishi PLC ( programmable controller )and Schneider touch screen control. The whole production process is working automatically.

3.Machine with high-pressure feed system, feeding mould fast, machine can install 36 pcs filling guns

4.Machine with vacuum system, it can make the cycle time shorter, cooling much faster, and reduce the moisture content of products, so that products moisture content of 8% or even less

5.Machine use double cylinder for the ejector frame, action smoothly and work coordination, to ensure not damage the products when ejecting

6.Machine pipe system use balancing valve and pressure sensor control, PID control so that heat penetrates quickly, lower energy consumption

7.Hydraulic system with large flow hydraulic pressure drive, move fast, lock mould even, low noise and energy saving, etc

Products:

Product detail pictures:

Related Product Guide:

Our target is always to satisfy our customers by offering golden support, superior value and high quality for professional factory for Polystyrene Machine - Auto Shape Molding Machine With Vacuum – WELLEPS , The product will supply to all over the world, such as: Spain, Florence, Boston, We are looking forward to establishing a mutually beneficial relationship with you based on our high-quality products, reasonable prices and best service. We hope that our products will bring you a pleasant experience and carry a feeling of beauty.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.