Professional Design Plastic Molding Types - EPS TV package mould – WELLEPS

Professional Design Plastic Molding Types - EPS TV package mould – WELLEPS Detail:

We have a professional and most experienced team to design and produce EPS moulds.

The mould production process is as follow 1. design the mould according customer’s products drawing or samples. 2. Send mould drawing to customer for customer’s confirm. 3. Produce the mould. 4. Test moulds to make the products. 5. Send samples to customers confirm. 6. Arrange shipment.

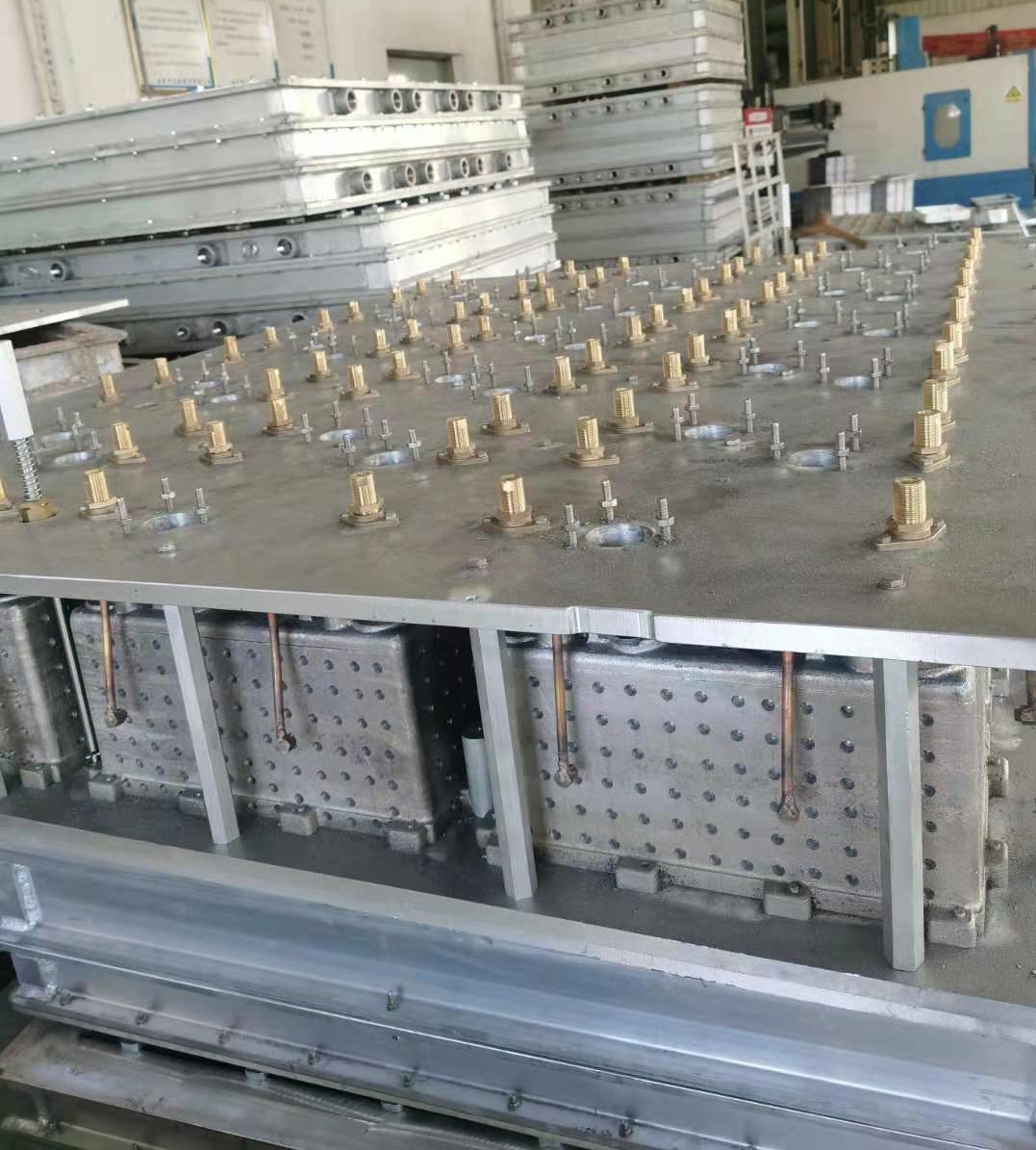

The whole mould is completely treated by CNC machine to ensure the size difference less than 0.1mm.

Mould coated with Teflon for better demould and the mould work smoothly in high temperature.

Mould use high-quality aluminum alloy material.

With special design for save steam and work more efficient.

We can design any kind EPS moulds according customer’s requirement. Only customers win, we can win.

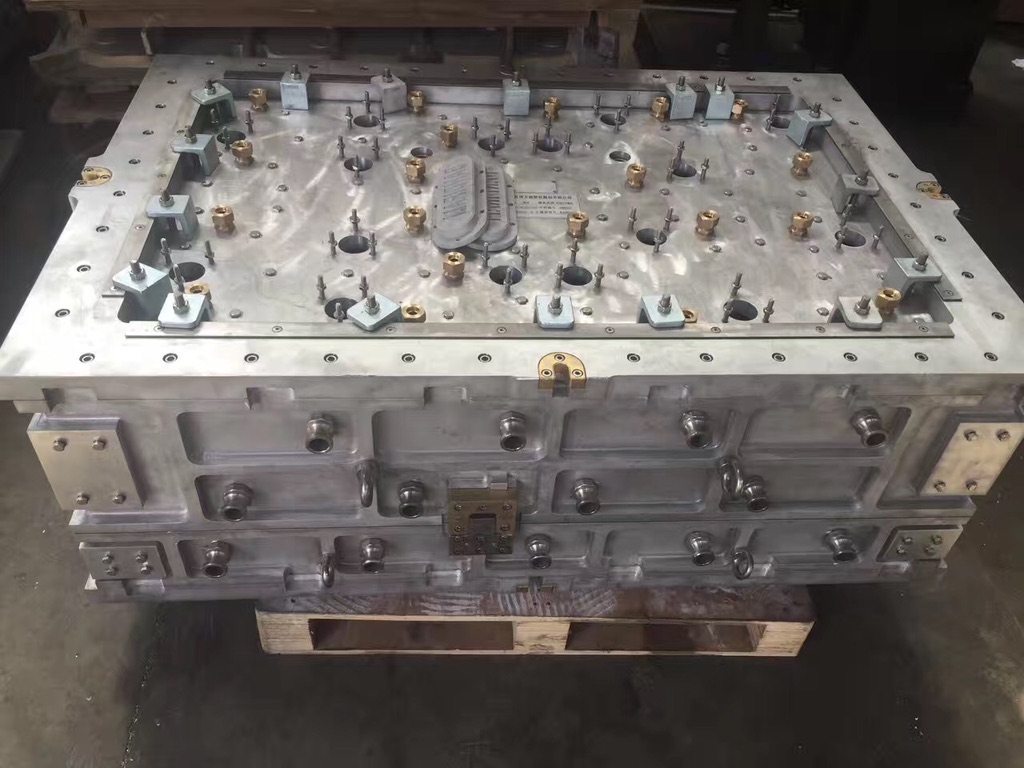

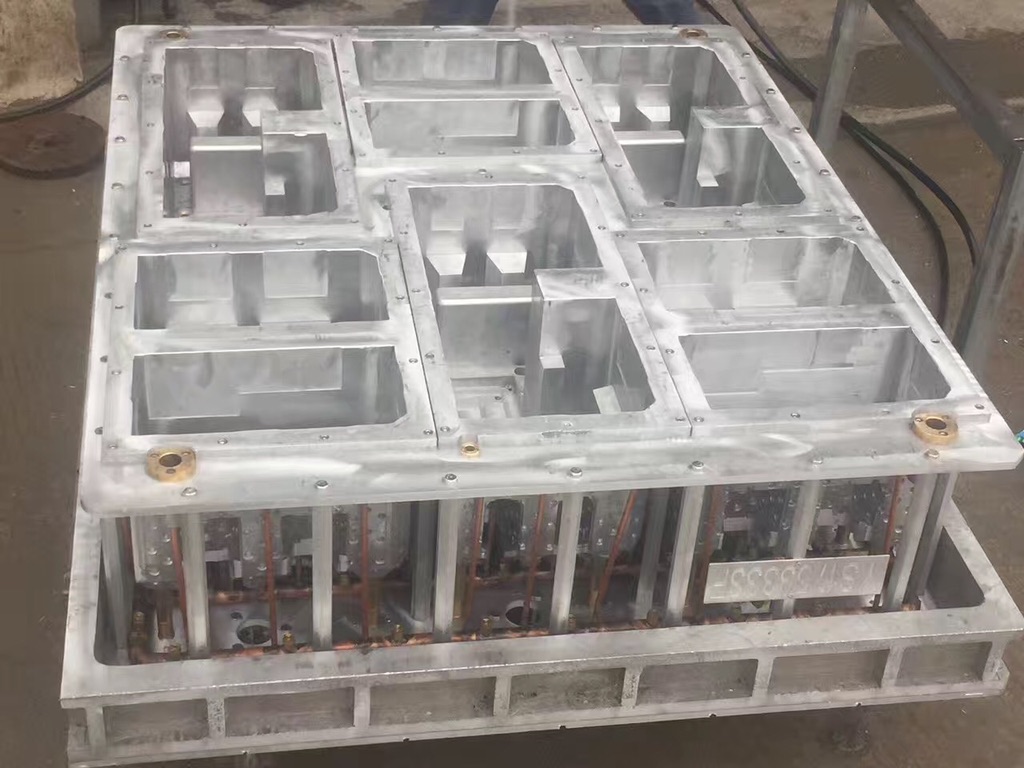

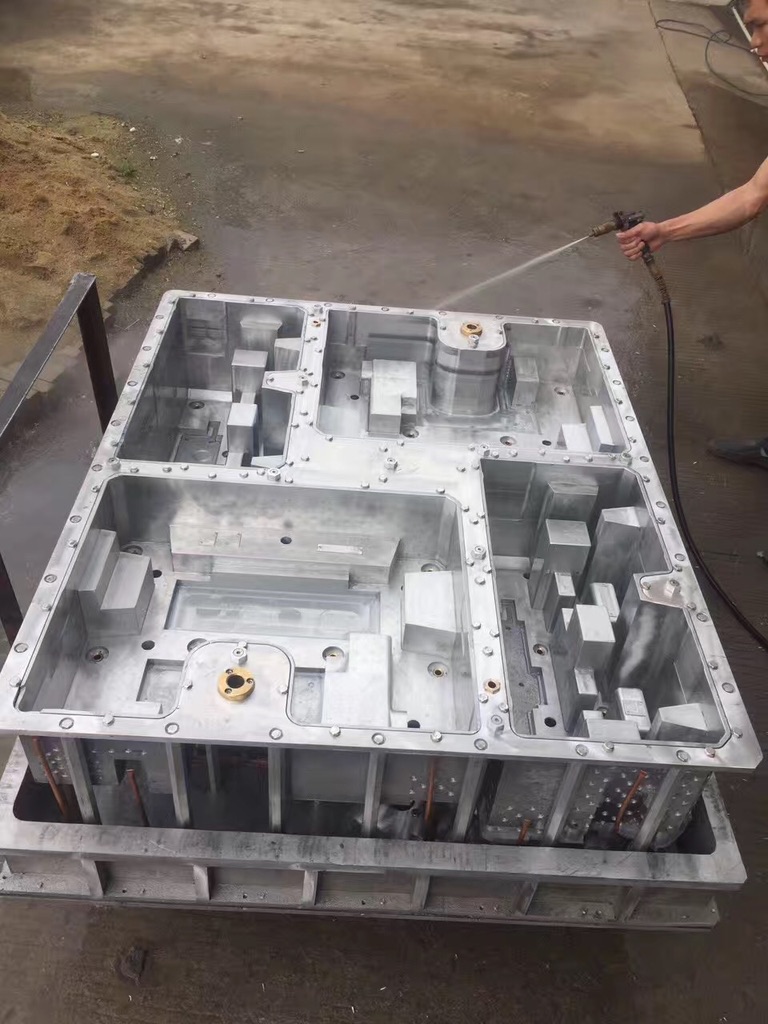

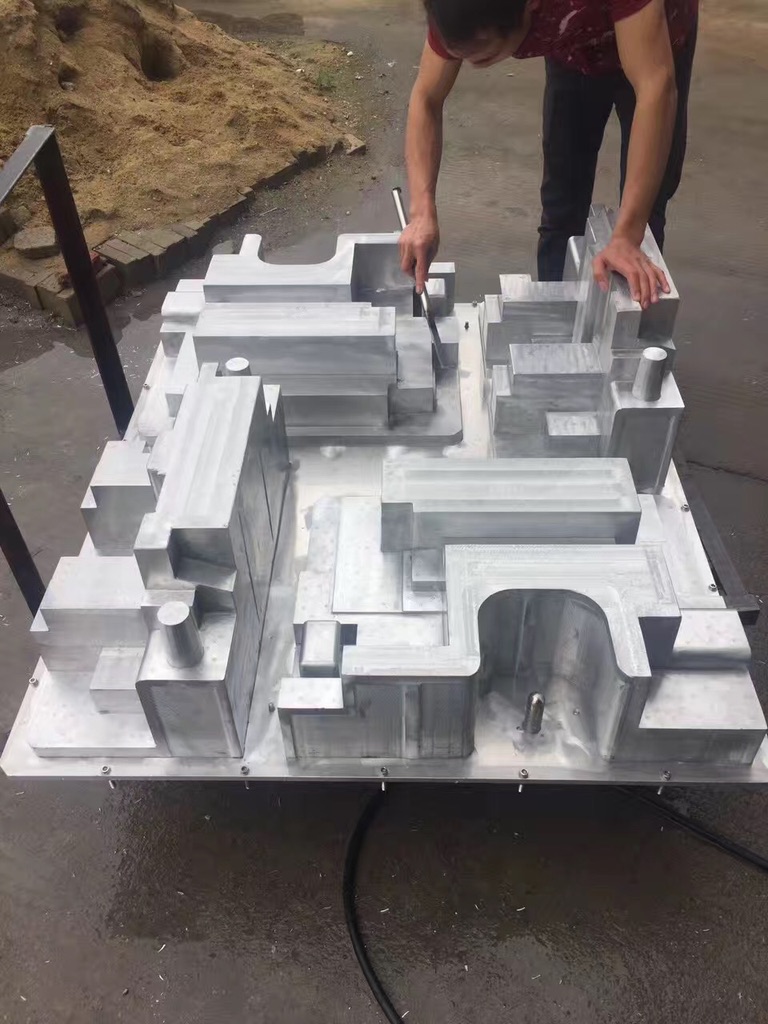

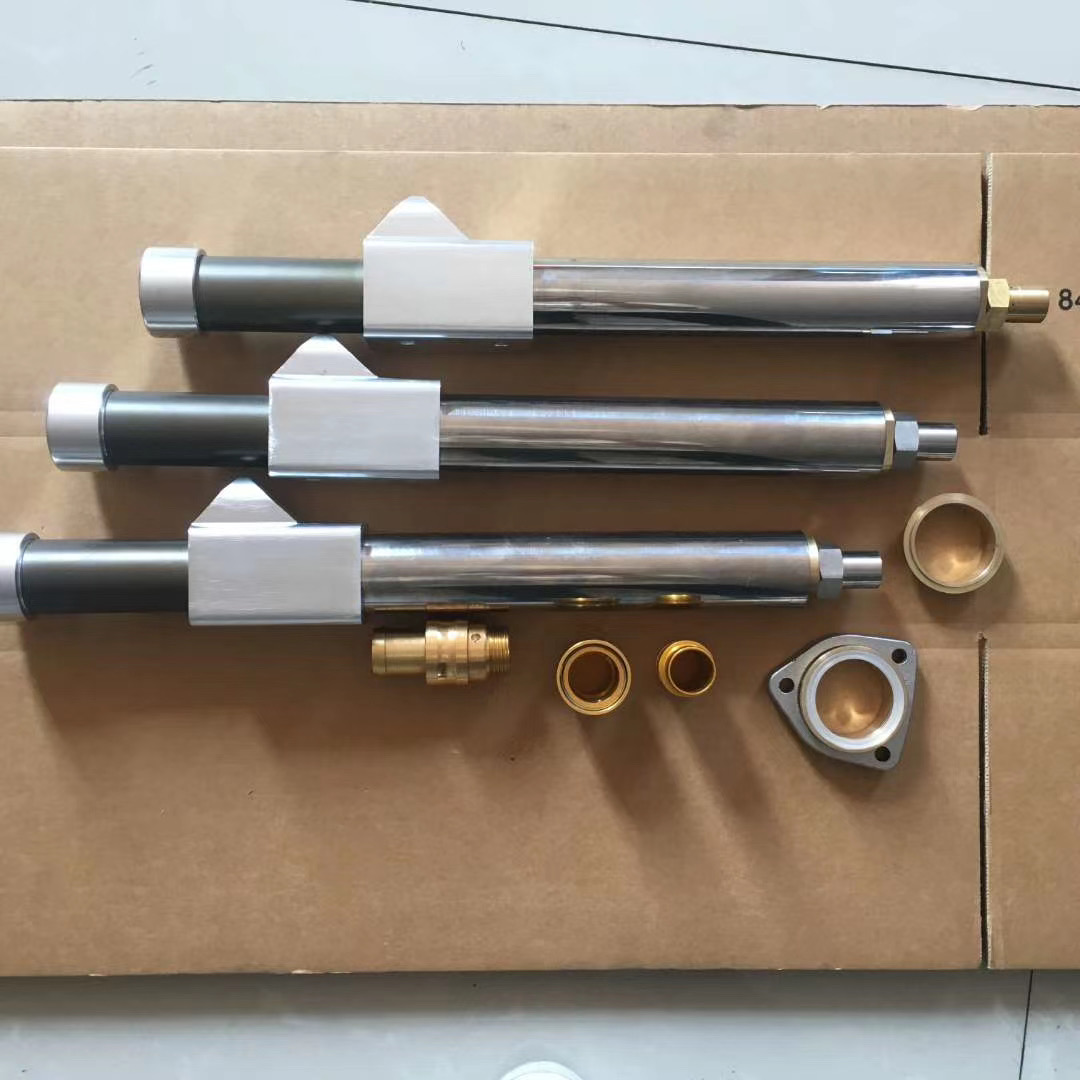

Finished moulds photos and moulds parts:

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for Professional Design Plastic Molding Types - EPS TV package mould – WELLEPS , The product will supply to all over the world, such as: New York, Austria, Cape Town, We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.