Professional Design Eps Moulds - wholesale eps styrofoam boxes making machine – WELLEPS

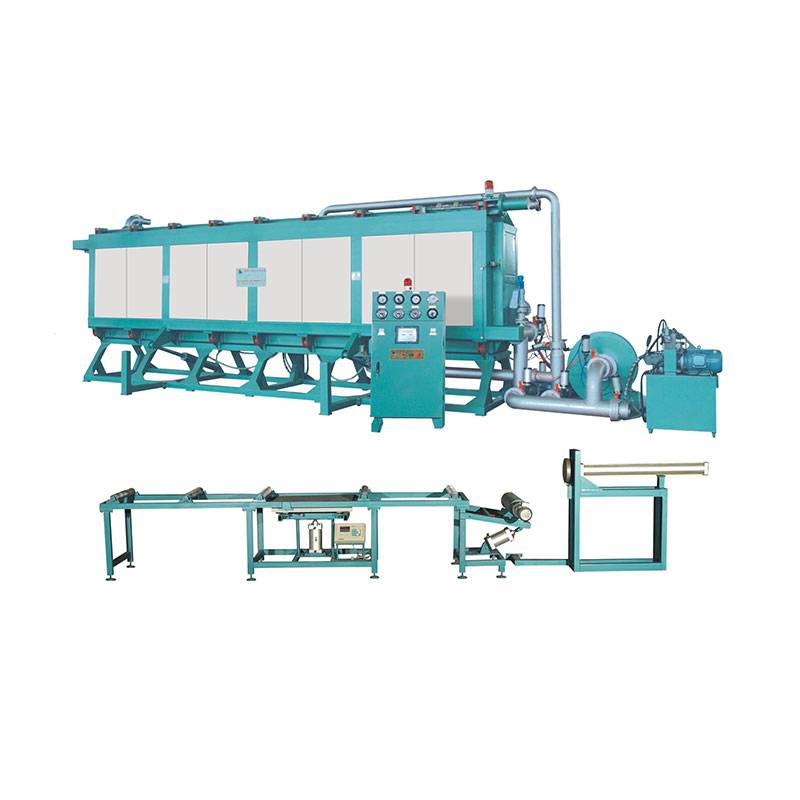

Professional Design Eps Moulds - wholesale eps styrofoam boxes making machine – WELLEPS Detail:

Main Advantage

Eps styrofoam boxes making machine products are widely used in industries such as vegetables and fish boxes, electrical parts packaging, wall and roof insulation, and house decoration.

1. Machine with PLC control work complete automatically.

2. Use good quality parts for the machine work very stable.

3. Use strong structure, machine work smoothly.

4. Produce good quality EPS products, the customers will win in the competitive market.

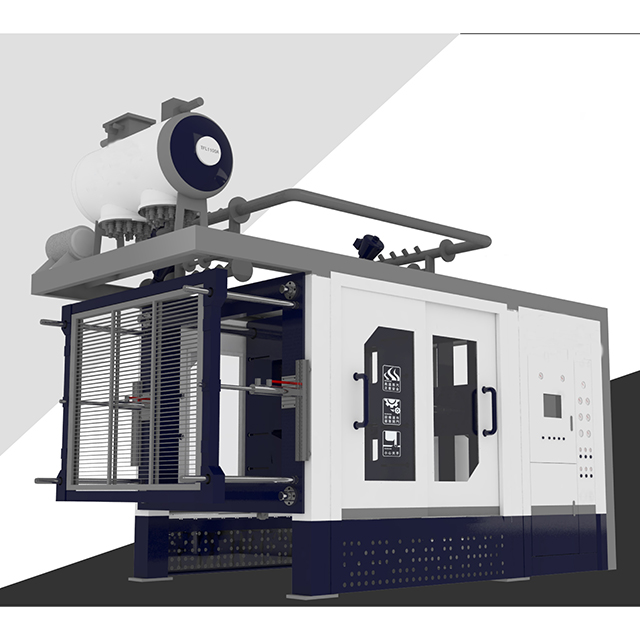

Machine Introduction

1.Equipment body use the high strength steel welded together, after the tempering process, sandblasting processing, to ensure the machine have strong structure, not get rust and increase the machine’s working life

2.Equipment adopts Mitsubishi PLC ( programmable controller )and Schneider touch screen control. The whole production process is working automatically.

3.Machine with high-pressure feed system, feeding mould fast, machine can install 36 pcs filling guns

4.Machine with vacuum system, it can make the cycle time shorter, cooling much faster, and reduce the moisture content of products, so that products moisture content of 8% or even less

5.Machine use double cylinder for the ejector frame, action smoothly and work coordination, to ensure not damage the products when ejecting

6.Machine pipe system use balancing valve and pressure sensor control, PID control so that heat penetrates quickly, lower energy consumption

7.Hydraulic system with large flow hydraulic pressure drive, move fast, lock mould even, low noise and energy saving, etc

Technical Data

| Item | Unit | Type | |||

| PSZ120T | PSZ160T | PSZ180T | |||

| Mould Dimension | mm | mm | 1200*1000 | 1600*1350 | 1800*1600 |

| Max Product Dimension | mm | mm | 1050*850*330 | 1420*1200*330 | 1600*1400*330 |

| Stroke | mm | 210-1360 | 270-1420 | 220-1370 | |

| Steam | Entry | mm | DN65 | DN80 | DN80 |

| Consumption | kg/cycle | (12-15T)Steam of 1T material | |||

| Cooling Water | Entry | mm | DN65 | DN65 | DN65 |

| Consumption | kg/cycle | 45-130 | 50-140 | 55-190 | |

| Compressed Air | Entry | mm | DN40 | DN50 | DN50 |

| Consumption | m3/cycle | 1.3 | 1.4 | 1.5 | |

| Vacuum Pump Capacity | m3/h | 165 | 280 | 280 | |

| Power | Kw | 11 | 16.5 | 16.5 | |

| Overall Dimension | L*W*H | mm | 4500*1840*2900 | 5000*2300*3400 | 5100*2550*3700 |

| Weight | kg | 4600 | 5700 | 6200 | |

| Cycle Time | s | 60-100 | 100-180 | 120-190 | |

Applications

Product detail pictures:

Related Product Guide:

The incredibly rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for Professional Design Eps Moulds - wholesale eps styrofoam boxes making machine – WELLEPS , The product will supply to all over the world, such as: Belgium, Armenia, Philadelphia, They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a must for yourself personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We have been confident that we will have a vibrant prospect and to be distributed all over the world in the years to come.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!