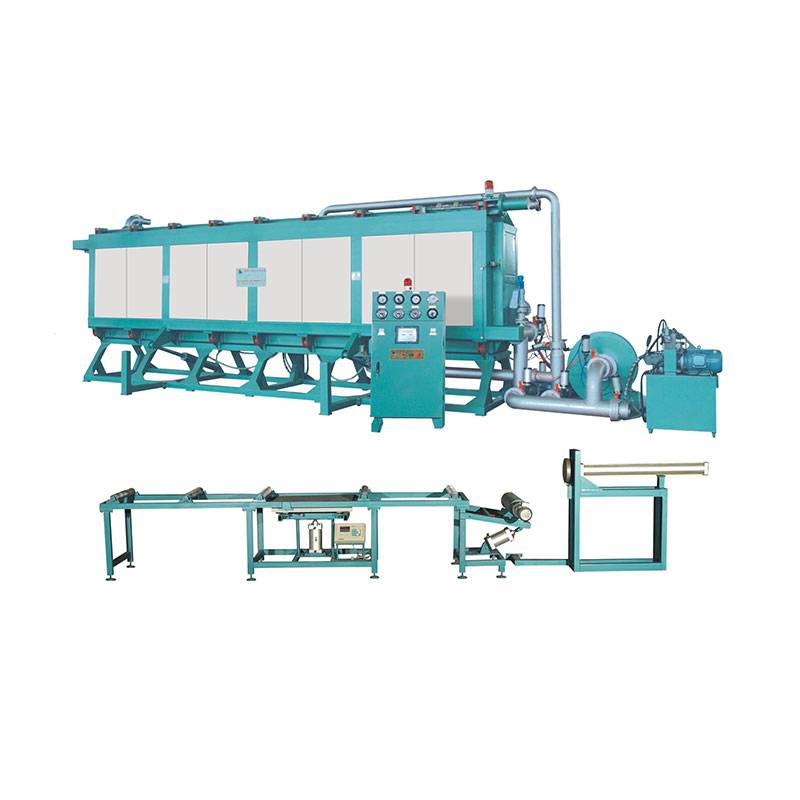

OEM/ODM Factory Vacuum Block Machine - Auto Shape Molding Machine With Vacuum – WELLEPS

OEM/ODM Factory Vacuum Block Machine - Auto Shape Molding Machine With Vacuum – WELLEPS Detail:

Main Features

1.Equipment body use the high strength steel welded together, after the tempering process, sandblasting processing, to ensure the machine have strong structure, not get rust and increase the machine’s working life

2.Equipment adopts Mitsubishi PLC ( programmable controller )and Schneider touch screen control. The whole production process is working automatically.

3.Machine with high-pressure feed system, feeding mould fast, machine can install 36 pcs filling guns

4.Machine with vacuum system, it can make the cycle time shorter, cooling much faster, and reduce the moisture content of products, so that products moisture content of 8% or even less

5.Machine use double cylinder for the ejector frame, action smoothly and work coordination, to ensure not damage the products when ejecting

6.Machine pipe system use balancing valve and pressure sensor control, PID control so that heat penetrates quickly, lower energy consumption

7.Hydraulic system with large flow hydraulic pressure drive, move fast, lock mould even, low noise and energy saving, etc

Products:

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of OEM/ODM Factory Vacuum Block Machine - Auto Shape Molding Machine With Vacuum – WELLEPS , The product will supply to all over the world, such as: Bahrain, Nigeria, Australia, We welcome customers from all over the world come to discuss business. We supply high quality products, reasonable prices and good services. We hope to sincerely build business relationships with customers from at home and abroad, jointly striving for a resplendent tomorrow.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!