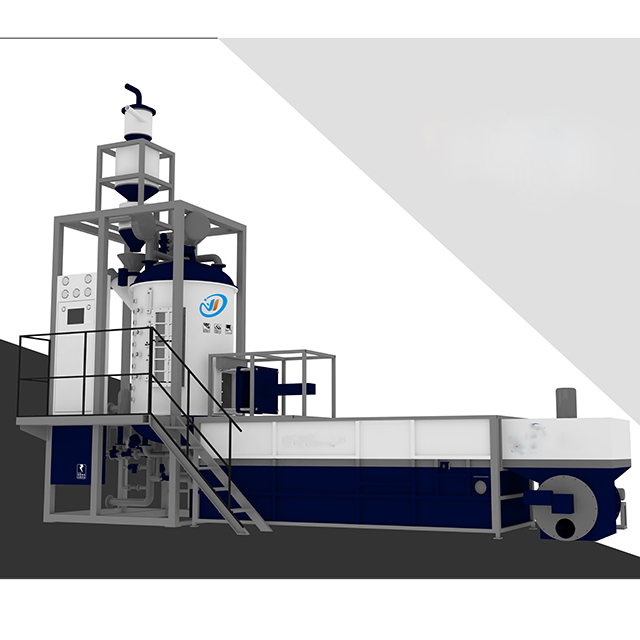

Eps Pre-Expander Machine is widely used in the field of foam products manufactured by the company.

After the eps pre expanded, a certain amount of foaming agent and water vapor are retained in the beads. After leaving the machine, the beads will condense into liquid. The liquid foaming agent will be dissolved in polystyrene again, which will rapidly reduce the pressure in the bubble and cause negative pressure (partial vacuum) in the bubble. The beads are very soft and easy to deform. During air supply, try not to make the air pressure too large, the inner wall of the air duct as smooth as possible, and the bending radius as large as possible (reduce collision resistance). The pipeline shall be a good conductor, and the whole line must be grounded to avoid electrostatic ignition. The transmission speed shall not exceed 8 m/s to avoid bead damage.

The beads just came out of the eps pre expander are wet. After being discharged from the pre expander, the foaming agent in the honeycomb cell condenses due to the absorption and sudden cooling of the air, forming a negative pressure in the cell. Therefore, beads must be placed for a period of time before hair. On the one hand, they are dry, on the other hand, they penetrate into the air to eliminate negative pressure, so that the pressure inside the bubble hole is balanced with the external pressure, so as to avoid the collapse of the bubble hole and make the beads elastic.

The EPS Pre-Expander Machine is an instrument, which must be maintained throughout the use process to prevent the function keys from being impacted or forced too hard, and to keep the external working voltage stable. Keep the interior of all control boxes dry and dust-free. Dust accumulation and humidity and cold for a long time are likely to cause problems in the switching power supply, control module, automobile relay and other electrical equipment inside the control box. Therefore, switch off the power supply immediately and remove it.

Post time: Mar-10-2023