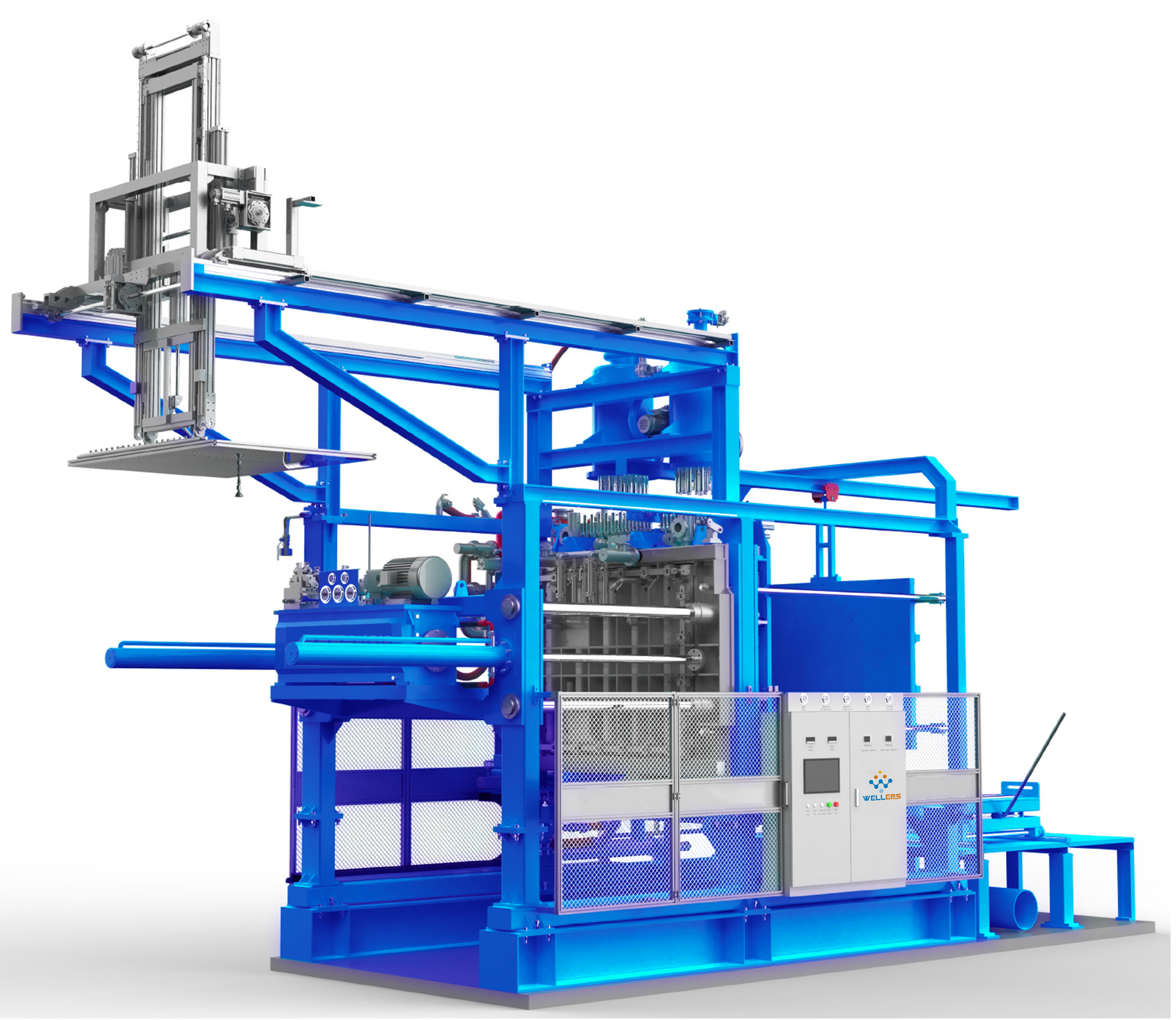

(1) EPS shape molding machine have good energy-saving characteristics. Adopting the main steam proportional pressure reducing valve technology, precise control can be achieved, and the steam pressure conveyed by the main pipeline is more stable. Compared with similar equipment, heating time can be reduced by 20% and energy consumption can be reduced by 30%.

(2) The EPS shape molding machine has a simple structure. The design with stronger stability and better strength greatly improves the strength value of the machine. The template can be high-temperature annealed and processed by CNC centers. On the one hand, it can ensure high accuracy, and on the other hand, it can greatly extend the service life of the machine.

(3) The EPS shape molding machine also has a dedicated cooling system. This system is very important, mainly using efficient vacuum system technology with low energy consumption. The large three-dimensional spray vacuum condenser sprays through a cooling water source to improve the vacuum condensation ratio, effectively protecting the vacuum pump and leaving the intermediate vacuum interface in advance.

(4) The control of the EPS molding machine is also very simple. Mainly operated through the touch screen. The operation method is very simple. At the same time, it also has an alarm system that can more systematically protect operators.

Post time: May-16-2023