Vertical EPS block moulding machine is special equipment for producing foam boards, which is widely used in insulation, packaging and construction industries. Unlike traditional horizontal forming machines, it optimises space utilisation and ensures uniform density and quality of foam boards.

Working Principle

The working principle of EPS vertical block moulding machine mainly includes three parts: pre-foaming module, moulding module and cooling module.

1. Pre-generation: EPS granules are added into the silo, and the EPS granules are expanded by heating and steam foaming. This process gradually turns the EPS granules into steam foamed bubbles.

2. Forming: A mixture of molten polystyrene and blowing agent is injected into a mould, which usually has a specific shape and size. As the mixture is injected, the bubbles gradually expand to fill the mould cavities and form the desired product shape.

3. Cooling and curing: The expanded polystyrene in the mould gradually cools, the bubbles stop expanding and eventually solidify. After the moulding is fully cured, the finished product is removed from the mould. Subsequent cutting and other processing can be continued.

Applicable industries

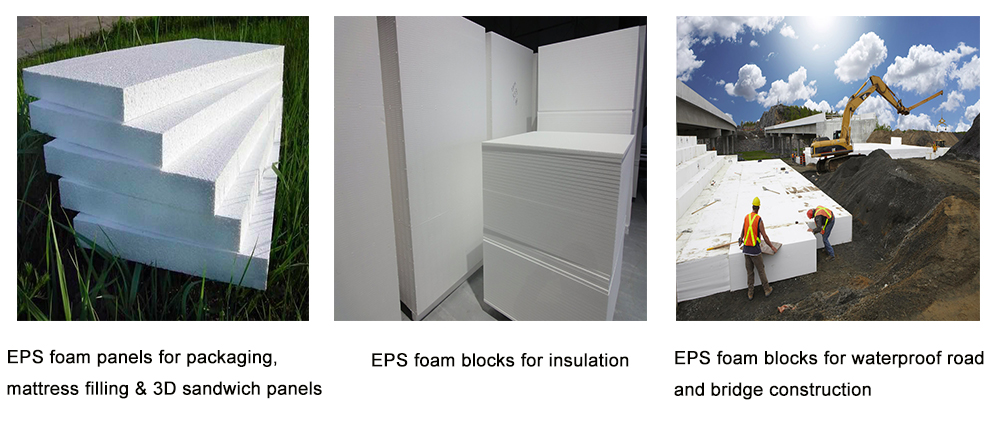

EPS vertical block moulding machine is widely used in production workshops, construction sites and other occasions for producing various EPS foam blocks, such as building insulation materials, packaging materials, handicrafts and so on.

In a word, EPS vertical block moulding machine is a kind of high efficient, stable and multi-functional production equipment, which can meet the needs of different industries for EPS foam blocks.

Post time: Jul-18-2024