EPP is short for Expanded polypropylene , a new type of foam plastic. EPP is polypropylene plastic foam material, is a kind of excellent performance of high crystal polymer/gas composite material, with its unique and superior performance has become the fastest growing environmental protection of the new compressive buffer heat insulation material.

EPP is also an environmentally friendly material that can be recycled. Compared with EPS (expanded polystyrene), EPP has higher mechanical strength, greatly expanding the application scenarios of foam plastics. EPP has light specific gravity, good elasticity, earthquake resistance, high deformation recovery rate, good absorption performance, oil resistance, acid resistance, alkali resistance, various chemical solvents, non-water absorption, insulation, heat resistance (-40 ~ 130℃), non-toxic and tasteless, can be 100% recycled and almost no decrease in performance, is the real environmentally friendly foam plastic. EPP beads can be moulded into various shapes of EPP products in the mould of the molding machine.

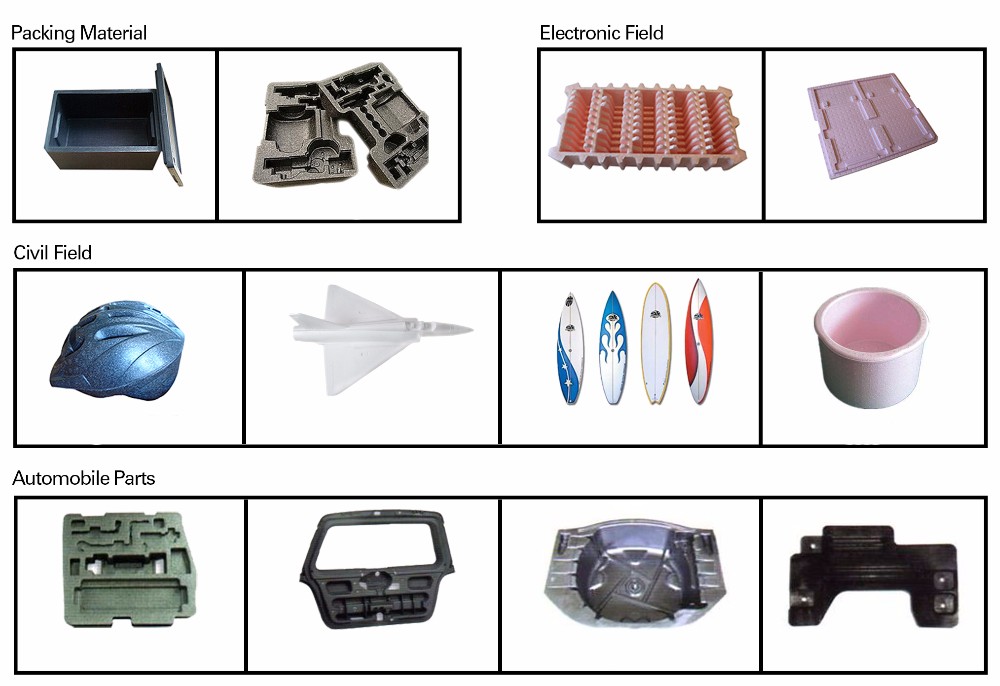

Welleps Technology Co., Ltd. has focused on developing and manufacturing EPS / EPP / ETUP machinery and molds for more than 15 years. The company has a professional team to provide customers with mechanical design, production and after-sales service.EPP Vacuum System Shape Moulding Machine is used to produce all kinds of valuables EPP packaging (such as notebook computers, liquid crystal displays, precision instruments), EPP toys (airplane models), EPP high-end car parts (EPP bumper, EPP toolbox, EPP sunshade etc.), EPP sporting goods (Surfboard, helmet, etc.).

Post time: Dec-27-2021