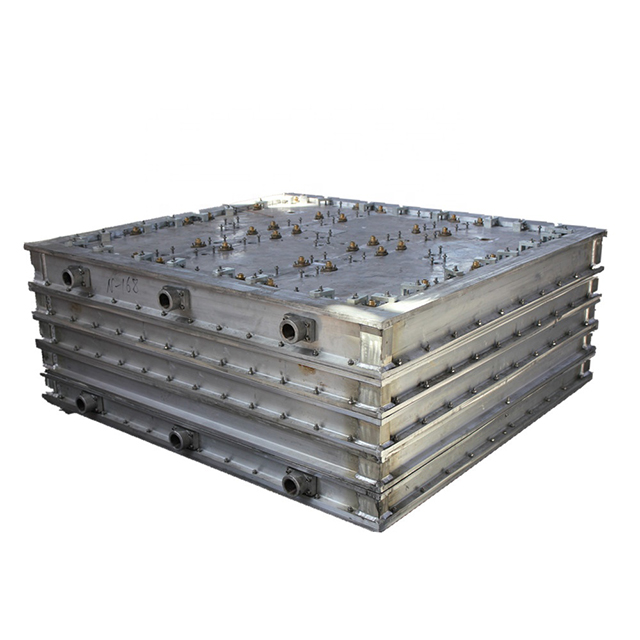

Hot Selling for Epp Yoga Roller Making Mould - Best Quality Automatic EPS Batch Pre-expander – WELLEPS

Hot Selling for Epp Yoga Roller Making Mould - Best Quality Automatic EPS Batch Pre-expander – WELLEPS Detail:

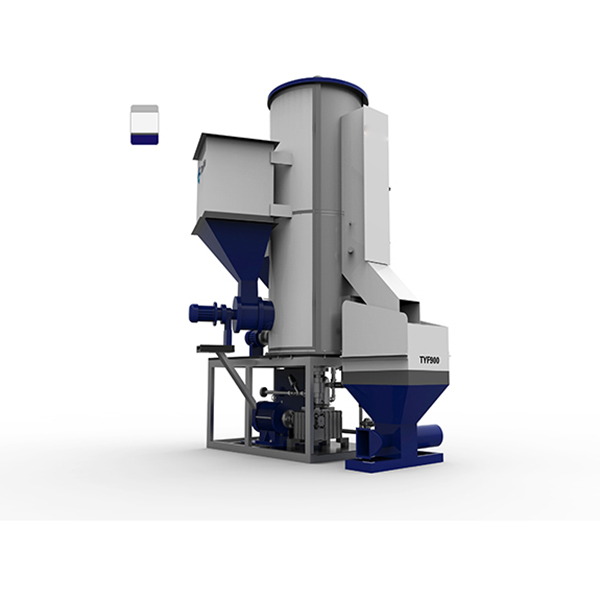

Main Features

1.Feeding, expander, filtrating, transport to silos automatically

2.Steam system controlled by pressure reducing valve and Angle seat valve, to achieve accurate heating

3.Feeding system adopts electronic weighing system, material level sensor control, so as to control capacity of foaming materials, to ensure that the foam bead evenly

4.Use PLC controller and touch screen, achieve precise automatic operation

5.Feed barrels made of stainless steel. Electrical components, valves are used abroad well-known brands, to maintain the durable, stable performa

Technical Data

| Item | Type | ||||

| PSJ110 | PSJ130 | PSJ150 | PSJ160 | ||

| Expansion Chamber | Diameter | Φ1100mm | Φ1300mm | Φ1500mm | Φ1600mm |

| Volume | 1.4m3 | 2.4m3 | 4.5m3 | 5.4m3 | |

| Useable Volume | 0.9m3 | 1.6m3 | 3.2m3 | 4.5m3 | |

| Steam | Entry | DN50 | DN65 | DN40 | DN100 |

| Consumption | 6-9kg/cycle | 10-12kg/cycle | 15-18kg/cycle | 18-20kg/cycle | |

| Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Compressed Air | Entry | DN25 | DN40 | DN50 | DN40 |

| Consumption | 0.5m3-0.6m3/cycle | 0.7m3-0.9m3/cycle | 0.5-0.6m3/cycle | 0.5m3-0.8m3/cycle | |

| Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Drainage | Drainage Port | DN80 | DN100 | DN100 | DN150 |

| Condensate | DN80 | DN100 | DN40 | DN50 | |

| Throughput | 12g/l 240kg/h | 12g/l 530kg/h | 12g/l 600kg/h | 12g/l 1500kg/h | |

| 15g/l 320kg/h | 15g/l 670kg/h | 15g/l 900kg/h | 15g/l 2000kg/h | ||

| 20g/l 430kg/h | 20g/l 920kg/h | 20g/l 1200kg/h | 20g/l 26000kg/h | ||

| 30g/l 600kg/h | 30g/l 1220kg/h | 30g/l 1500kg/h | 30g/l 3100kg/h | ||

| Material Conveying Line | Φ150mm | Φ250mm | Φ150mm | Φ250mm | |

| Power | 16.13Kw | 20.3Kw | 24.85Kw | 38.45Kw | |

| Density | 12-30g/l | 12-30g/l | 12-30g/l | 12-30g/l | |

| Density Tolerance | ≤±3% | ≤±3% | ≤±5% | ≤±3% | |

| Overall Dimension | L*W*H | 5600*3800*4530 | 7380*3000*4500 | 4310*4150*5120 | 11000*2840*6050 |

| Weight | 3500kg | 4200kg | 5000kg | 8000kg | |

| Room Height Required | 5000mm | 5500mm | 6000mm | 7000mm | |

| Auto density-weighing system | optional | optional | optional | ||

| Second expansion | optional | include | optional | ||

Application

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to each individual client, but also are ready to receive any suggestion offered by our buyers for Hot Selling for Epp Yoga Roller Making Mould - Best Quality Automatic EPS Batch Pre-expander – WELLEPS , The product will supply to all over the world, such as: Thailand, America, Philippines, If you need any of our products, or have other items to be produced, please send us your inquiries, samples or detailed drawings. Meanwhile, aiming to develop into an international enterprise group, we look forward to receiving offers for joint ventures and other cooperative projects.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!

Write your message here and send it to us