Hot New Products Boiler Parts - Automatic Continuous Polystyrene EPS Foam Cup Making Machine – WELLEPS

Hot New Products Boiler Parts - Automatic Continuous Polystyrene EPS Foam Cup Making Machine – WELLEPS Detail:

Main Features

1. EPS Foaming-Cup Production Line is widely applied in producing large amount of hot coffee cup, hot tea cup, hot soup blow, noodle tub and other food and beverage packing .

2. Light weight, good rigidity and well heat isolation.

3. The machine holds many merits such as high foaming times, high producing efficiency, low steam consumption, low cost and different model products are made at same time.

4. Pipes and tubes of the transferring system are all made from stainless material so that they resist eroding and easy to be cleaned.

5. Pre-expand and forming procedures are all operated by automatic controller, the mechanical and electrical device or apparatuses are all from international famous brand

Technical Data

| Total Forming Area (L*W) | mm | 1200*280 |

| Forming Capacity | Second/mould | 7-15s |

| Foam Cup/Bowl Size | OZ | 6-32 |

| Power Consumption | kw/h | ≤0.3 |

| Steam Pressure | MPa | 0.6-0.9 |

| Cooling Water Pressure | MPa | 0.4-0.5 |

| Air Pressure | MPa | 0.6-0.9 |

| Machine Overall Size (L*W) | mm | 1300*500 |

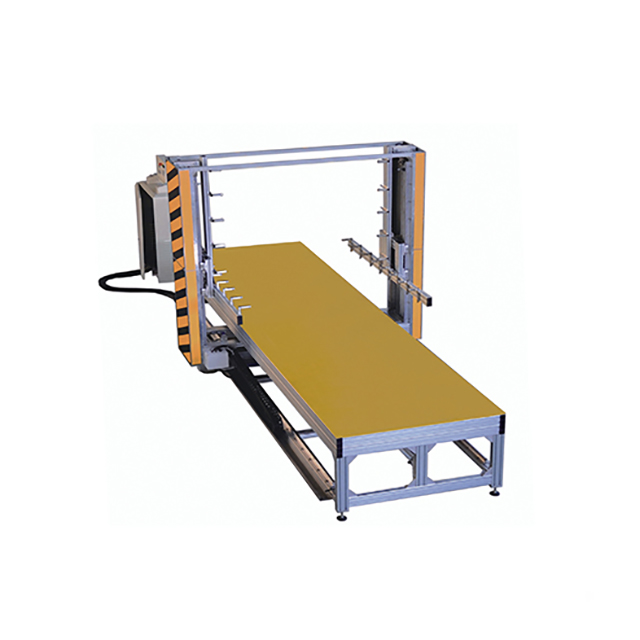

Detail Drawing

Product Application

Product detail pictures:

Related Product Guide:

We are commitment to offer you the aggressive price tag ,exceptional products and solutions high-quality, as well as fast delivery for Hot New Products Boiler Parts - Automatic Continuous Polystyrene EPS Foam Cup Making Machine – WELLEPS , The product will supply to all over the world, such as: Puerto Rico, Pakistan, France, We put the product quality and customer's benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, allow us to work together to get success.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.

Write your message here and send it to us