factory customized High Pressure Air Compressor - High efficient Automatic EPS Shape Molding Machine – WELLEPS

factory customized High Pressure Air Compressor - High efficient Automatic EPS Shape Molding Machine – WELLEPS Detail:

Technical Data

| Item | Unit | PSZ100T | PSZ140T | PSZ175T | |

| Moule Dimension | mm | 1000*800 | 1400*1200 | 1750*1450 | |

| Max Product Dimension | mm | 850*650*330 | 1220*1050*330 | 1550*1250*330 | |

| Stroke | mm | 210-1360 | 270-1420 | 270-1420 | |

| Cooling Water | Entry | mm | DN65 | DN65 | DN65 |

| Consumption | kg/cycle | 45-130 | 50-140 | 55-190 | |

| Compressed Air | Entry | mm | DN40 | DN40 | DN50 |

| Consumption | m³/cycle | 1.3 | 1.4 | 1.5 | |

| Vacuum Pump Capacity | m³/h | 165 | 250 | 280 | |

| Power | kw | 11 | 14.5 | 16.5 | |

| Overall Dimension | L*W*H | mm | 4500*1640*2700 | 4600*2140*3100 | 5000*2550*3700 |

| Weight | kg | 4100 | 4900 | 6200 | |

| Cycle Time | s | 60-90 | 60-150 | 120-190 | |

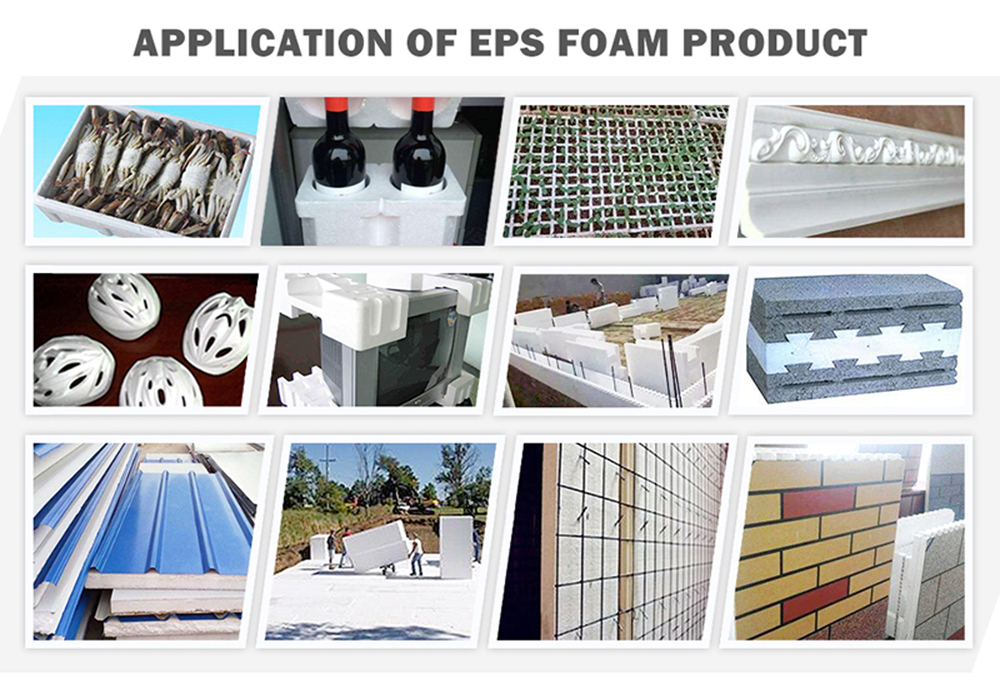

Application Field:

EPS products widely industry such as vegetable and fish box, electric parts package, wall and roof indulation, house decoration and etc.

Products:

Main Feature:

1.Machine use strong structure, normally use 20 mm thickness Q345 high strength steel plate. Machine plate and pipe system with hot galvanized, that it is not easy to get rust

2.Machine adopts the best size calculation and clear pipe system, ensures a rapid pressurization and reduce pressure process. Machine use steam system balancing valve and pressure sensor control, PID control so the machine have accurate heating and energy saving, short heating time, rapidly improve the running speed of the equipment

3.Machine use PLC control, touch screen operation, the system with self protection and alarm system, electrical components adopt international famous brand, guarantee the safe operation

4.Machine has made great improvement on seals, all fast connector using liquid sealant to seal, use nylon tube instead of the traditional PU tube, prolong the service life and can effectively prevent the air leakage, with more energy savings

5.Machine vacuum use spray cooling device, machine working mainly use vacuum cooling then water cooling. That the machine working faster and the product moisture content of less than 8%

6.Welleps Machine with double hopper, can produce two different density product at one time, Hopper was special designed, it can keep pressure very well.

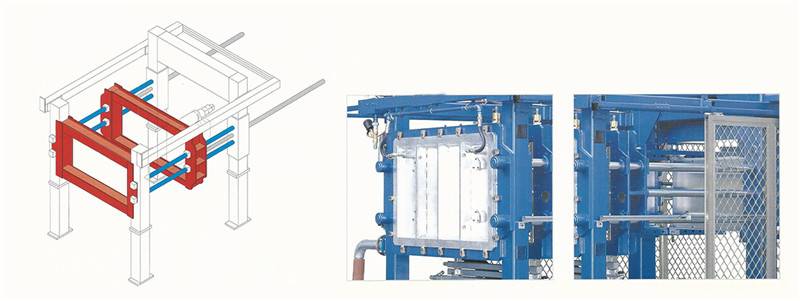

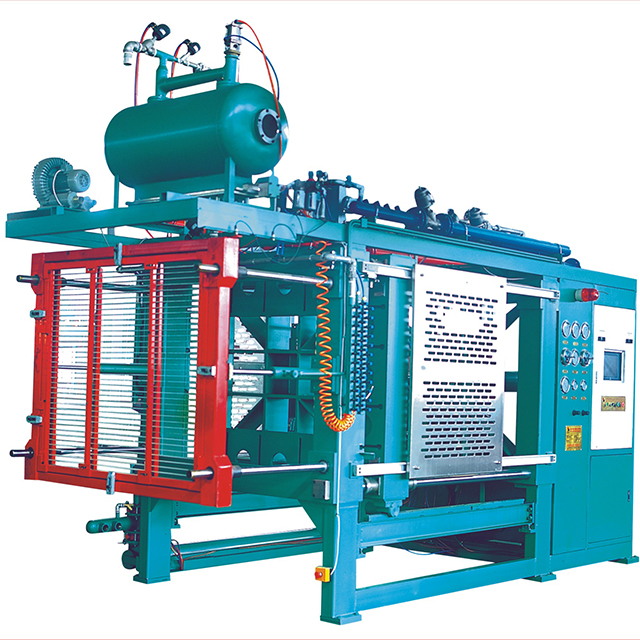

THE MACHINERY STRUCTURE:

This system does not require any lubricant. The hydraulic cylinder is installed in the two sides of the doom with even mould clamping force. The stainless dome can hold the heat. The mold opening and mould closing are managed by the computerized system which can ensure the best feeding accuracy. The mould ejection motion is controlled by the ejection system to provide the best quality of precision product during the ejection process.

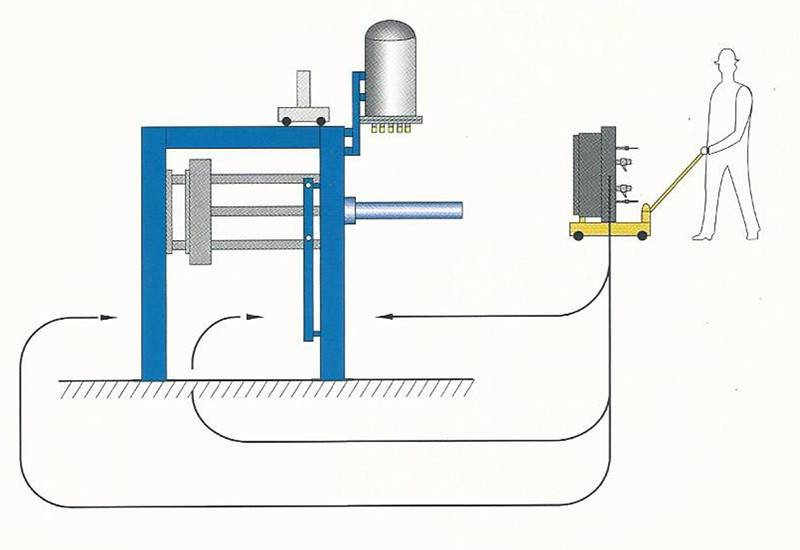

THE LAYOUT OF THIS MACHINE

This machine is designed as a three-dimension open space. This open-space design will fasten the mold changing process and operators can change the mold from the front, back and two sides of this machine. Also, this machine can be placed directly on the ground without setting any platform. To secure the safety of the operators, this machine is equipped with safety door and security system.

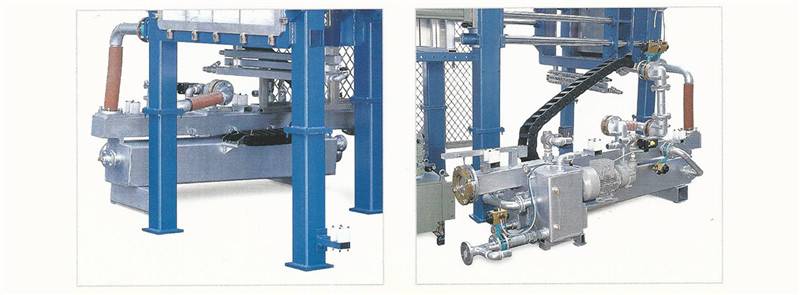

VACUUM SYSTEM:

The vacuum system is equipped with the Liquid Ring Vacuum pump and condenser which provides more efficient vacuity. Without any extra drying step, we can speed up the injection under this vacuum system. The mold ejection is easy to be completed and also save the more energy.

Remarks:

We can design machine according customer’s detail requirement.

Machine in customers’ factory:

Product detail pictures:

Related Product Guide:

Our firm sticks to the basic principle of "Quality is the life of your company, and status will be the soul of it" for factory customized High Pressure Air Compressor - High efficient Automatic EPS Shape Molding Machine – WELLEPS , The product will supply to all over the world, such as: New Orleans, Florence, Finland, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.