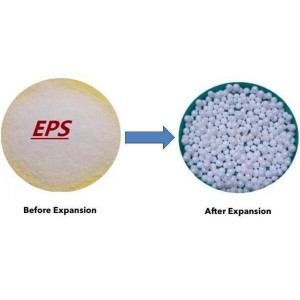

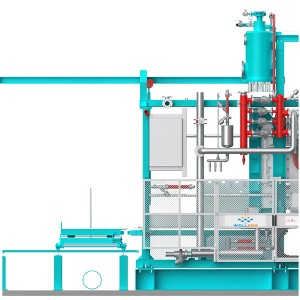

EPS Pre-expander Foam Beads EPS Beans Filling Machine

Main advantage

1. Fully automatic production.

2. Controlled by touch screen and PLC, easy to operate.

3. High output and save energy.

4. Exact density of foam beads.

5. Stable quality and less failure.

Main Features

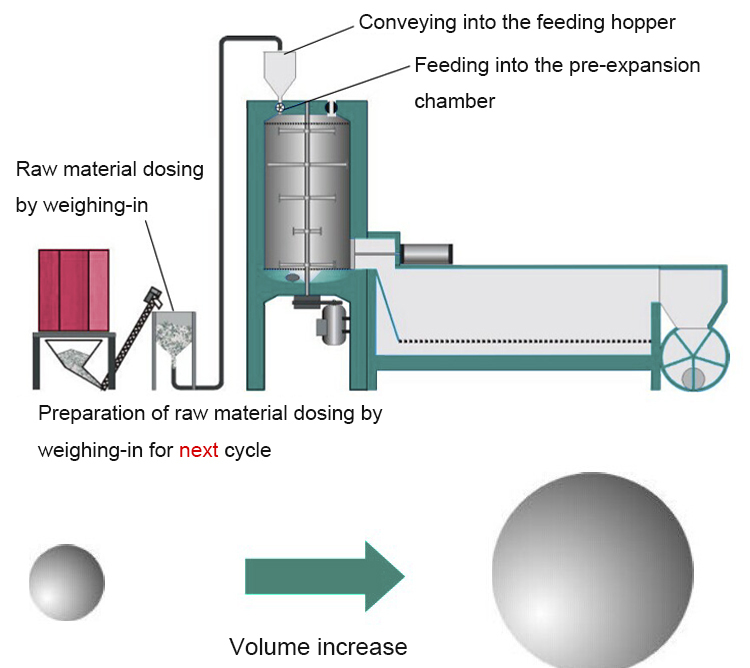

1.Automatic feeding, electronic weighing, temperature control, material level control to realize automatic and continuous production.

2.Electronic weighing system and material level control system ensure the density of the foamed beads, which make the beads uniform and keep the density tolerance within 2%.

3.Japan original pressure reducing valve controls the steam pressure of the chamber, which ensures the outcome pressure of the valve constant and the inner temperature stable, which keeps the foamed material equal and prevents the beads agglomerate because of the bad temperature control.

4.Adopt PLC and touch screen, achieve precise automatic operation

5.Feed barrels made of stainless steel. Most of the main component are world-famous brand, with reliable performance, stable quality, long service life and low maintenance cost.

6.Automatic discharging from the pre-expander, which can automatically filter and crush the ball material and transport the foamed material to silos.

Technical Data

| Item | Type | ||||

| PSJ90 | PSJ130 | PSJ150 | PSJ160 | ||

| Expansion Chamber | Diameter | Φ900mm | Φ1300mm | Φ1500mm | Φ1600mm |

| Volume | 0.85m3 | 2.4m3 | 4.5m3 | 5.4m3 | |

| Useable Volume | 0.6m3 | 1.6m3 | 3.2m3 | 4.5m3 | |

| Steam | Entry | DN40 | DN65 | DN40 | DN100 |

| Consumption | 2-4kg/cycle | 10-12kg/cycle | 15-18kg/cycle | 18-20kg/cycle | |

| Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Compressed Air | Entry | DN25 | DN40 | DN50 | DN40 |

| Consumption | 0.3m3-0.4m3/cycle | 0.7m3-0.9m3/cycle | 0.5-0.6m3/cycle | 0.5m3-0.8m3/cycle | |

| Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Drainage | Drainage Port | DN100 | DN100 | DN100 | DN150 |

| Condensate | DN40 | DN100 | DN40 | DN50 | |

| Throughput | 13g/l 240kg/h | 12g/l 530kg/h | 12g/l 600kg/h | 12g/l 1500kg/h | |

| 18g/l 350kg/h | 15g/l 670kg/h | 15g/l 900kg/h | 15g/l 2000kg/h | ||

| 25g/l 480kg/h | 20g/l 920kg/h | 20g/l 1200kg/h | 20g/l 26000kg/h | ||

| 31g/l 590kg/h | 30g/l 1220kg/h | 30g/l 1500kg/h | 30g/l 3100kg/h | ||

| 50g/l 720kg/h | |||||

| Material Conveying Line | Φ150mm | Φ250mm | Φ150mm | Φ250mm | |

| Power | 16.75Kw | 20.3Kw | 24.85Kw | 38.45Kw | |

| Density | 12-90g/l | 12-30g/l | 12-30g/l | 12-30g/l | |

| Density Tolerance | ≤±2% | ≤±3% | ≤±5% | ≤±3% | |

| Overall Dimension | L*W*H | 4500*2000*4900 | 7380*3000*4500 | 4310*4150*5120 | 11000*2840*6050 |

| Weight | 2500kg | 4200kg | 5000kg | 8000kg | |

| Room Height Required | 5000mm | 5500mm | 6000mm | 7000mm | |

| Auto density-weighing system | optional | optional | optional | ||

| Second expansion | optional | include | optional | ||

Products