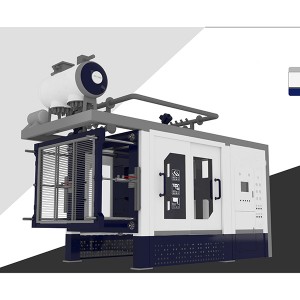

EPS Moulding Machine

Main Advantage

Hydraulic System:

*Adopt famous brand hydraulic components, differential pressure system design, can achieve high speed, low noise operation, the fastest mold opening and closing speed can reach 350mm/sec, can achieve high speed and efficient stable operation;

*Two-point mold opening and closing, the latest mold clamping technology and mechanism, can stabilize the mold clamping pressure, the equipment is not easy to leak during production, and effectively improve the energy consumption (steam) utilization rate.

Pipeline System:

The pipeline inlet and outlet adopt the most optimized design to reduce the waste of energy consumption and reduce the response speed.

The design of the cooling water pipe makes the water cooling fast and efficient; the design of the cavity copper pipe ring makes the surface of the products smoother.

Molding System:

The use of electrical digital proportional valve makes the pressure in the mold cavity linearly stable, ensuring the stability of product quality.

The latest heating system bypass pipeline design effectively reduces the molding time and steam energy consumption.

Control System:

*Adopt Siemens intelligent control system and humanized windows system operation interface to make the operation more convenient and intelligent;

*The imported electric proportional valve plus linear position sensor and pressure sensor are used to efficiently and perfectly cooperate with the control system to make the feeding, heating, blowing, water cooling and other work more accurate, stable, reliable and efficient;

*The latest production molding technology makes it convenient and efficient control equipment to effectively improve production efficiency

Mold Change System:

One-touch Mold Change System is an updated version from Fast Mold Change Series, now it only takes 5 minutes.

Technical Data

| Item | Unit | Type | |||

| PSZ1412 | PSZ1714 | PSZ19145 | |||

| Mould Dimension | mm | mm | 1200*1400 | 1400*1700 | 1400*1900 |

| Max Product Dimension | mm | mm | 1000*1200*350 | 1200*1500*350 | 1200*1700*350 |

| Stroke | mm | 210-1580 | 210-1580 | 210-1580 | |

| Steam | Entry | inch | 4(DN100) | 4(DN100) | 4(DN100) |

| Consumption | kg/cycle | 6 | 7 | 8 | |

| Cooling Water | Entry | inch | 3(DN80) | 3(DN80) | 3(DN80) |

| Consumption | L/cycle | 1--1.5 | 1--3 | 1--3 | |

| Compressed Air | Entry | inch | 2.5(DN65) | 2.5(DN65) | 2.5(DN65) |

| Consumption | L/cycle | 1.1 | 1.1 | 1.1 | |

| Vacuum Pump Capacity | m3/h | ≤200 | ≤200 | ≤200 | |

| Power | Kw | 9 | 11 | 13.2 | |

| Overall Dimension | L*W*H | mm | 9200*3000*5000 | 9200*3300*5100 | 9200*3500*5300 |

| Cycle Time | S/cycle | 40-50 | 45-60 | 45-60 | |

| 注:受原料特性和气候差异影响,生产能力仅供参考 | |||||

| Note:production capacity is only for reference,because of different raw material and climate | |||||

Applications