EPS lost foam casting machine

Main Advantage

1.Solid steel construction processed by high temperature annealing, heat treatment, surface de-rusted by sandblast and sprayed by anti-corrosive paint.

2.Control system adopts Japan PLC and English touch screen for easy operating and fully automatic producing.

3.High quality and stable machines parts, like German Burkert angle-seat valves.

4.Energy saving by well-designed machine size, pipe lines to realize fast steam pressure increasing and decreasing.

5.High flow hydraulic drive with double hydraulic cylinder, which makes machine running steadily and locking tightly.

6.The machine can be equipped with a build-in vacuum system, and also there is an access to center vacuum system.

7.Double feeding chamber for fast feeding to shorten the cycle time.

8.Balance valve for stable steam controlling.

9.Extended zinc coated machine legs are optional for customer for installing machine on special ground.

10.Machine legs and platform is optional.

Machine Introduction

To accommodate with different sized product, the machine has a variety of templates, the smallest size is about 600×800 mm. The maximum size can reach 1200 × 1400 mm.This machine is equipped with two-step hydraulic system, compressed feeding system, and central energy system, relief damper, holding-pressure water tank, condensation system, computer-controlled system, digital process control system and steam room.

The vacuum system is equipped with the Liquid Ring Vacuum pump and condenser which provides more efficient vacuity. Without any extra drying step, we can speed up the injection under this vacuum system. The mold ejection is easy to be completed and also save the more energy.

The adjustment of energy pressure is very important. Under higher steam pressure, the production time will be prolonged and consume more energy. However, the final product might be deformed and the surface appearance of the product might be affected when the pressure is too low. The relief damper functions when releasing mold and heating up the mold. The compressed air is used for filling and this damper will reduce the consumption of energy and provide high quality product.

This machine has one full set of central energy system which is produced by our company All steam and air which are needed during the injection process are controlled by the central energy system valve. This system will provide even air intake and can be adjusted easier. This low-pressure steam system is designed with enlarged pipes and valves which can provide best working condition.

Technical Data

| Item | PSZ100T | PSZ140T | PSZ175T | |

| Mould Dimension | 1000*800 | 1400*1200 | 1750*1450 | |

| Max Product Dimension | 850*650*330 | 1220*1050*330 | 1550*1250*330 | |

| Stroke | 210-1360mm | 270-1420mm | 270-1420mm | |

| Steam | Entry | DN65 | DN80 | DN80 |

| Consumption | (12-15T)Steam of 1T material | |||

| Cooling Water | Entry | DN65 | DN65 | DN65 |

| Consumption | 45-130kg/cycle | 50-140kg/cycle | 55-190kg/cycle | |

| Compressed Air | Entry | DN40 | DN40 | DN50 |

| Consumption | 1.3m3/cycle | 1.4m3/cycle | 1.5m3/cycle | |

| Vacuum Pump Capacity | 165m3/h | 250m3/h | 280m3/h | |

| Power | kw | 11kw | 14.5kw | 16.5kw |

| Overall Dimension | L*W*H (mm) | 4500*1640*2700 | 4600*2140*3100 | 5000*2450*3500 |

| Weight | kg | 4100 | 4900 | 6000 |

| Cycle Time | s | 60-90s | 60-150s | 100-180s |

| Note:We can make Automatic Eps Styrofoam Mold Making Machine according to customer requirement. | ||||

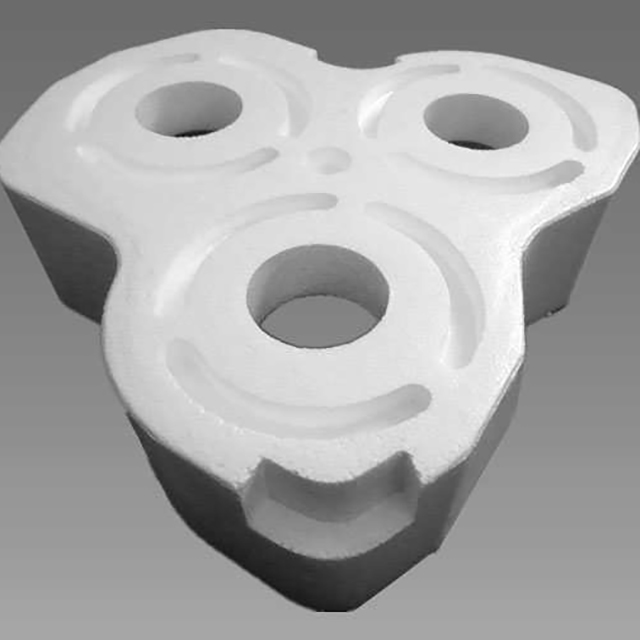

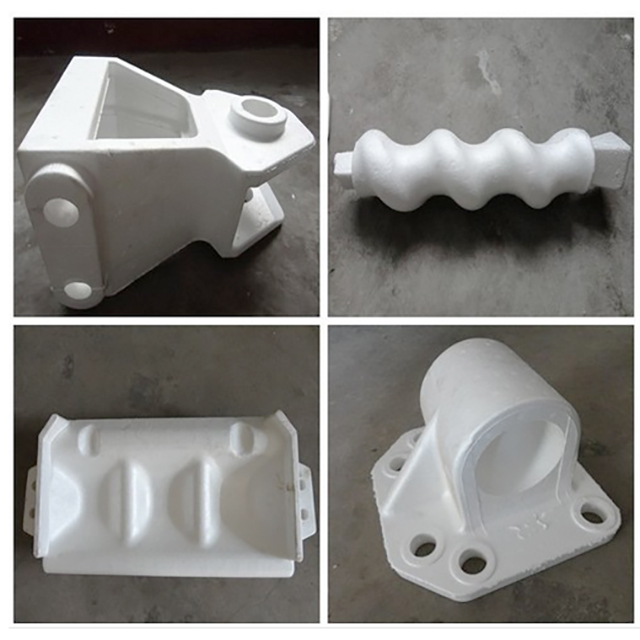

Applications