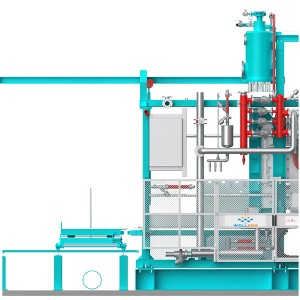

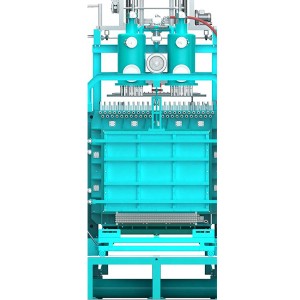

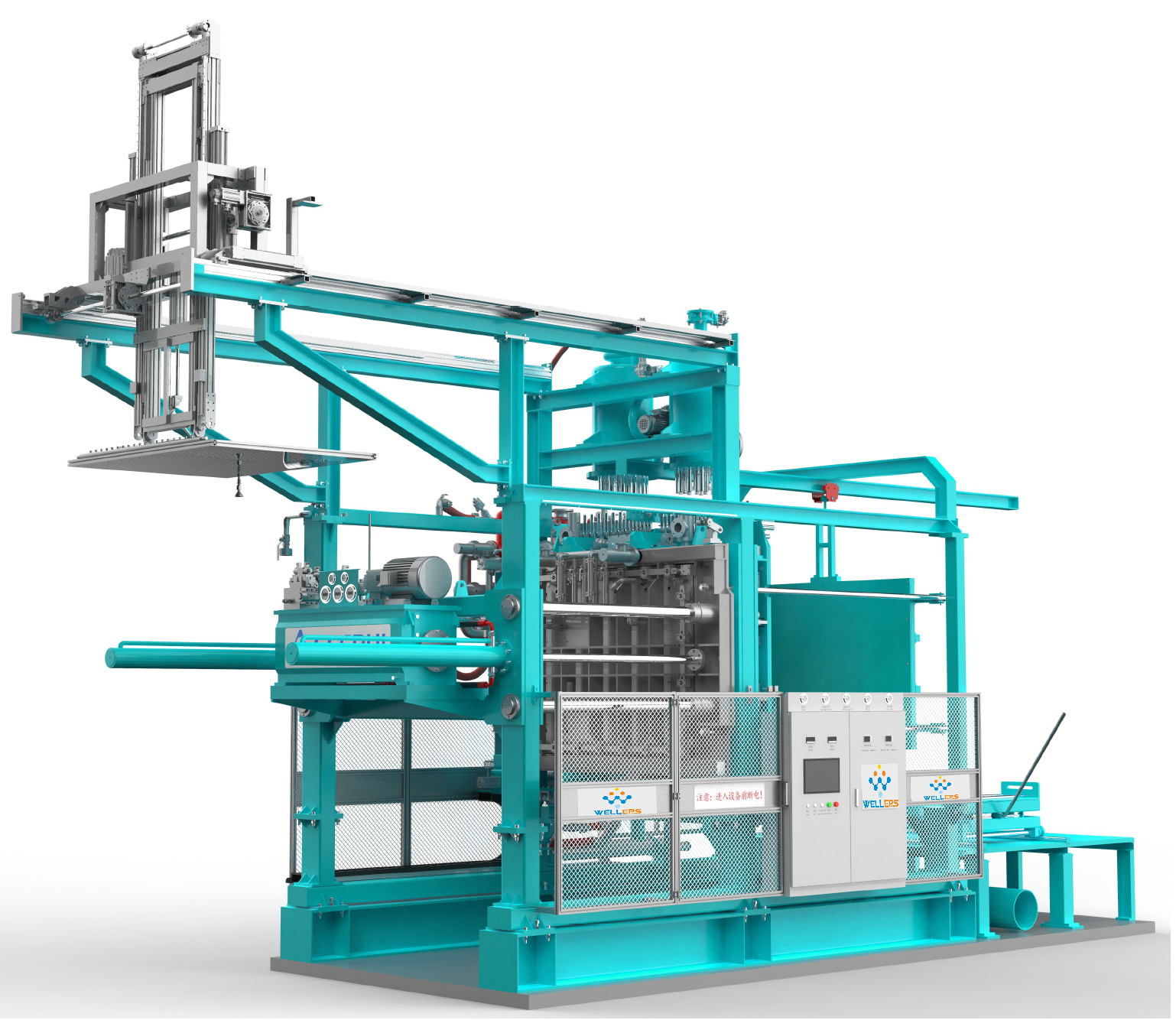

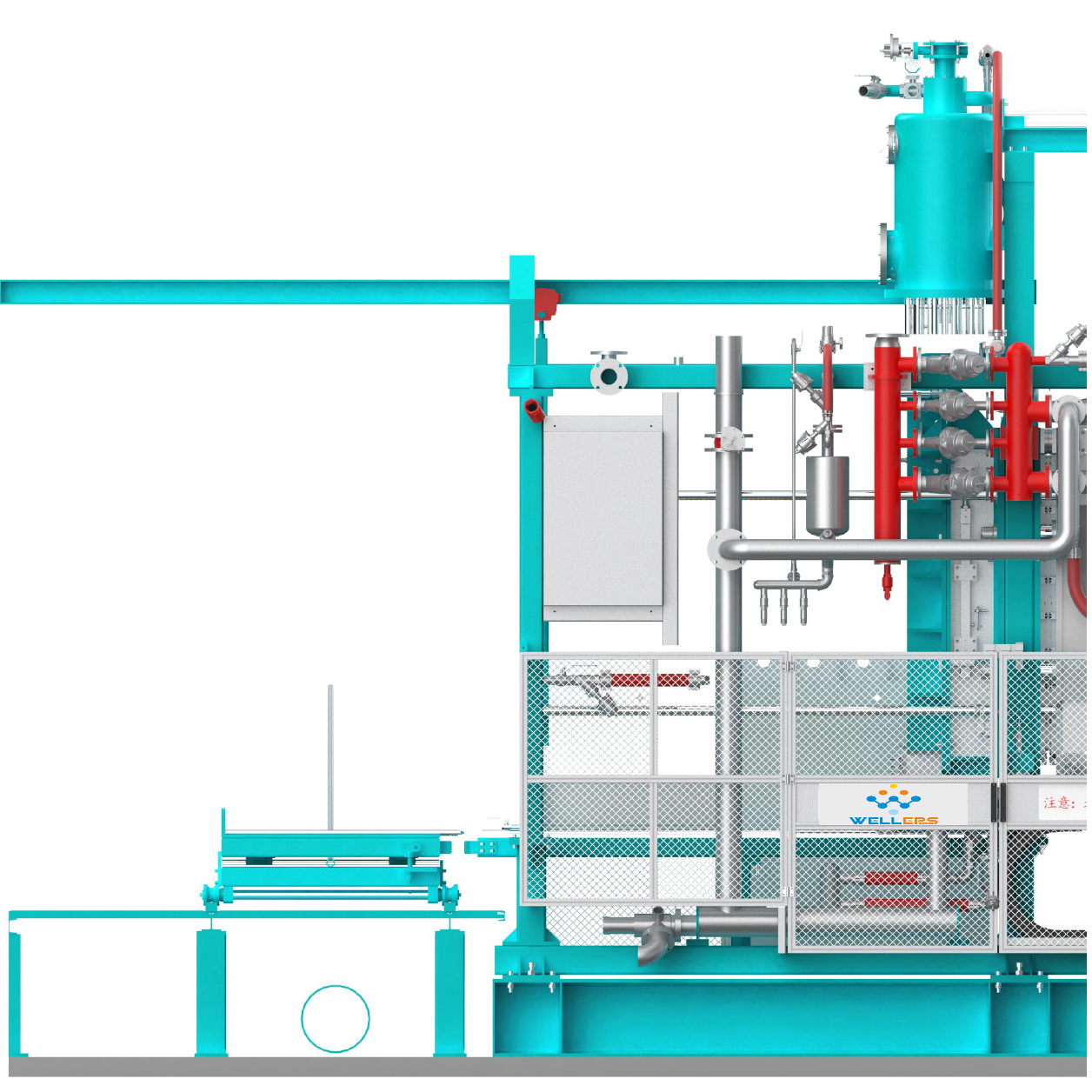

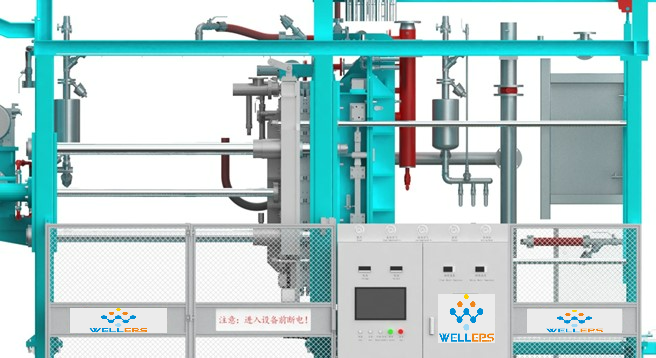

Fast Mould Change EPS Shape Molding Machine

Main Advantage

Fast mould change eps shape molding machine allows the easy and completely automatic managing of the whole moulding cycle, offering the operator recipes already defined and tested and giving him, at the same time, the opportunity of modifying their wide range of sequences and combinations.

Cycles: various sequences combining the phases of moulding, inserting, film loading, thermo filming, filming,withdrawing and unloading.

Working recipes: each item to be moulded is associated to a specific cycle with all technological data (times, pressures, positions, etc.) pre-set for the various phases of production/work.

Production / work phases: for each specific phase various technological data could be pre-set and they are the result of all years of experience and are all automatically controlled and managed.

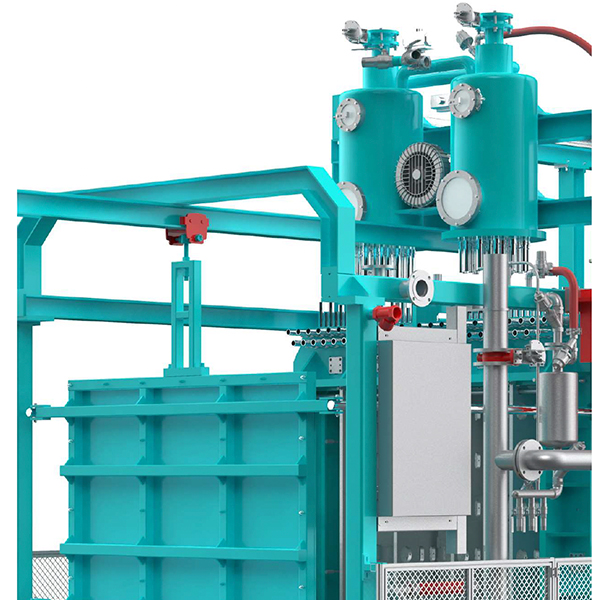

vaporization: several different types of vaporisation controlling and combining according to the different requirements, steam, condense, sintering, wait, under pressure keeping, stabilization, normalization, venting, clearing with time and pressure control, choice of the side and pressure control type

demoulding: by air, by vacuum, by mechanic extractors; intermediate cycle phase,cycle ending with time controlling, height, pressures.

Machine Introduction

Fast mould change eps shape molding machine structure in steel, electro-welded, sandblasted and varnished with epoxy paint.

Fast mould change eps shape molding machine mould chambers and their supports in welded steel with normalisation and anti- corrosion treatment (cold metallization). Moving side guided by 4 columns, with guiding bushes in self-lubricant sintered bronze, operated by two hydraulic cylinders. The movement of the moving chamber is controlled by encoder with a precision of 2/10 of mm. Automatic research of machine zero each switching on of the control panel. Automatic pre-heating of the mould each switching on of the control panel.

Fast mould change eps shape molding machine 2 EPS INDEPENDENT hoppers - capacity 120 lt complete with motorization

Fast mould change eps shape molding machine adopt Italian digital proportional control energy saving system

Fast mould change eps shape molding machine has a global exclusive automatic quick mold change system (5 minutes)

Fast mould change eps shape molding machine with automatic robot for piece picking

Technical Data

| Item | PSZ100T | PSZ140T | PSZ175T | |

| Mould Dimension | 1000*800 | 1400*1200 | 1750*1450 | |

| Max Product Dimension | 850*650*330 | 1220*1050*330 | 1550*1250*330 | |

| Stroke | 210-1360mm | 270-1420mm | 270-1420mm | |

| Steam | Entry | DN65 | DN80 | DN80 |

| Consumption | (12-15T)Steam of 1T material | |||

| Cooling Water | Entry | DN65 | DN65 | DN65 |

| Consumption | 45-130kg/cycle | 50-140kg/cycle | 55-190kg/cycle | |

| Compressed Air | Entry | DN40 | DN40 | DN50 |

| Consumption | 1.3m3/cycle | 1.4m3/cycle | 1.5m3/cycle | |

| Vacuum Pump Capacity | 165m3/h | 250m3/h | 280m3/h | |

| Power | kw | 11kw | 14.5kw | 16.5kw |

| Overall Dimension | L*W*H (mm) | 4500*1640*2700 | 4600*2140*3100 | 5000*2450*3500 |

| Weight | kg | 4100 | 4900 | 6000 |

| Cycle Time | s | 60-90s | 60-150s | 100-180s |

| Note:We can make Fast mould change EPS shape molding machine according to customer requirement. | ||||

polystyrene applications

Fast mould change EPS shape molding machine its major application is as protective packaging for consumer electronic products . Its excellent thermal insulation and mechanical protection properties make it ideal to package fish and other foodstuffs.

EPS Foam Packaging

EPS corner packaging

Expanded Polystyrene box