CNC EPS Cutter foam cutting machine

Main Features

CNC EPS Cutter foam cutting machine

1.The aluminum frame is highly stable and accurate

2.The cutting line adopts stepping motor which is very stable and could be timing freely,this matches the requirement for cutting special shapes with frequently changeable timing,the accuracy is 0.5mm

3. Equipped with a piece of 3KW transformer, adjustable power output ranges from 0 to 7V under electrical control.

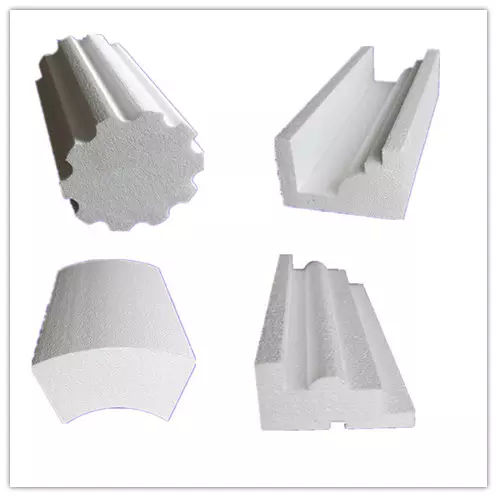

4. Ability to synchronously cut 20 pieces of identical figures or letters due to 20 heating cords mounted on the cutting frame.

5. Specialized touch screen controller, easy to set parameters; 3B codes of the cutting figures/letters can be input to the

controller from the U memory disk, the simple codes of figures can be entered on the touch screen.

6. The cnc foam cutting machine process can be showed on the display screen; cutting speed is adjustable (max. 4000mm/min).

7. With function of cutting stroke protection: when exceeds the regulated cutting stroke, the machine can stop running

automatically

8. With functions of parameters memory while fail of electricity; reverse cutting and rotating, mirror symmetry; clearance

Technical Data

| Item | Unit | Type | |||

| SPC200D | SPC300D | SPC400D | |||

| Max cutting block size | mm | 2000*1500*(1250-1500) | 3000*1500*(1250-1500) | 4000*1500*(1250-1500) | |

| Cutting wire | mm | Φ0.4mm | Φ0.4mm | Φ0.4mm | |

| Cutting speed | m/min | 0-4 | 0-4 | 0-4 | |

| Cutting transformer | Capacity | KVA | 3 | 3 | 3 |

| Voltage | V | 0-70 | 0-70 | 0-70 | |

| Machine size | mm | 3500*2500*2600 | 4200*2500*2600 | 5200*2500*2600 | |

| Weight | Kg | 600 | 700 | 820 | |

| Note:We can make machine according the customer's requirement | |||||

ATTENTION

1.EPS block should be dried before cutting to increase efficiency and avoid damage of hot wires;

2.Check cutting machine before operation to ensure reliability of ground connection, correct running direction of main cutter, air blower and limit switch;

3.Strictly prevent foam beads and cutting fragments entering into the electric system to avoid conflagration because this equipment is a strong electric current working system;

4.Maintenance and attention points of variable-speed gear box.

5.Replace lubricating oil in gear box every half a year.

6.Keep enough lubrication oil in oil tank and check it regularly;

7.Pay attention to running condition of whole equipment during its working, Stop to check when there is any unusual situation.

8.Notice: Do not whack the gear box.

9.Fire Extinguisher must be prepared at working site and operator should monitor the machine during operation;

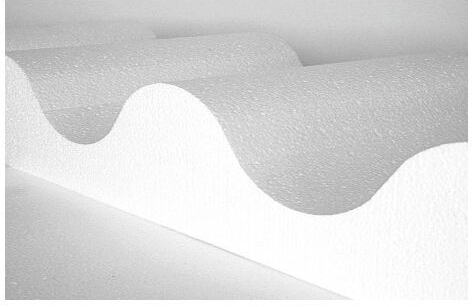

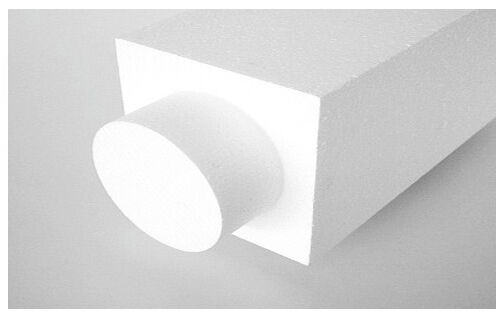

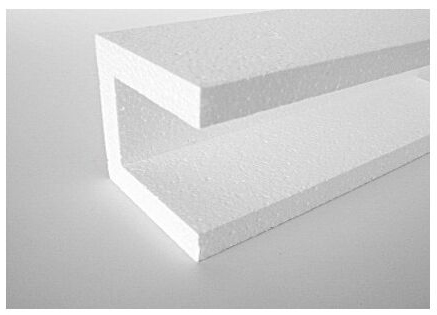

Products