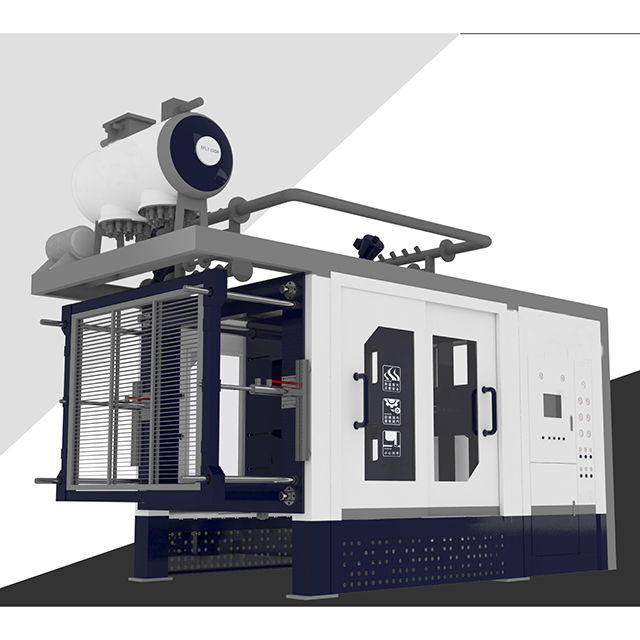

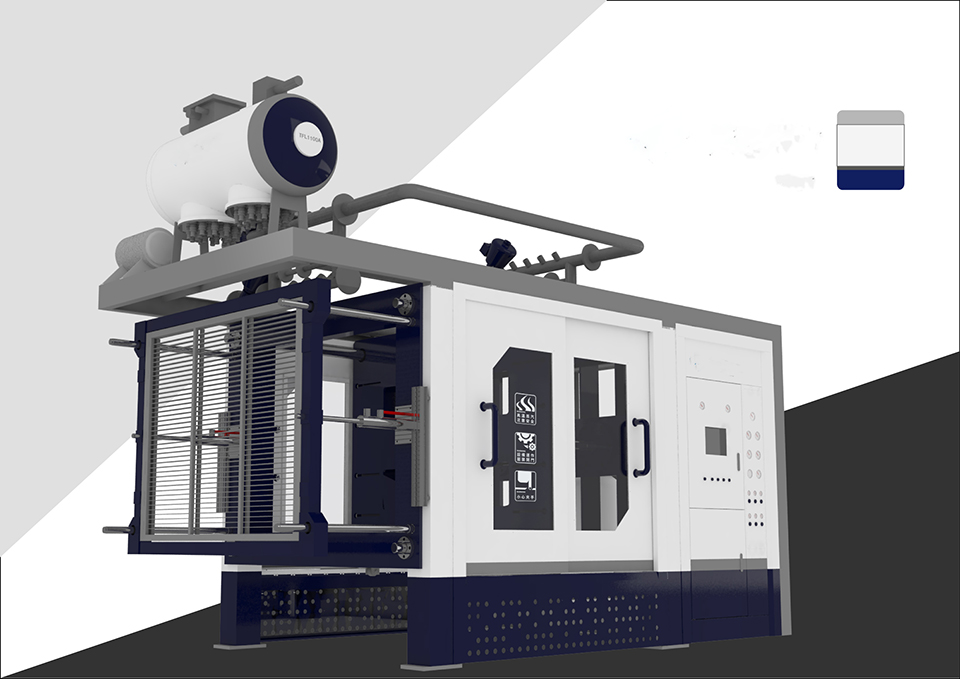

EPP styrofoam package thermocol molding machine

product description

Expanded Polypropylene (EPP) is a highly versatile closed-cell bead foam that provides a unique range of properties, including outstanding energy absorption, multiple impact resistance, thermal insulation, buoyancy, water and chemical resistance, exceptionally high strength to weight ratio and 100% recyclability.

Automatic EPP Moulding Machine is used to produce all kinds of valuables EPP packaging (such as notebook computers, liquid crystal displays, precision instruments), EPP toys (airplane models), EPP high-end car parts (such as EPP bumper, EPP toolbox, EPP sunshade, etc.), EPP sporting goods (such as Surfboard, helmet, etc.).

Main Features

1.Equipment body use the high strength steeel welded together, after the tempering process, sandblasting processing, to ensure the machne have strong structure, not get rust and increae the machine's working life.

2.Equipment adopts Mitsubishi PLC(programmable controller) and touch screen control. The whole production process is working automatically.

3.Machine with high-pressure feed system, feeding mould fast,machine can install 36 pcs filling guns.

4.Machine with wacuum system, it can make the cycle time shorter ,cooling much faster ,and reduce the moisture content of products, so that products moisture content of 8% or even less.

5.Machine use double cylinder for the ejector frame, action smoothly and work coordination, to ensure not damage the products when ejecting.

6.Hydraulic system with large flow hydraulic pressure drive, move fast, lock mouled even, low noise and energy saving,etc.

Technical Data

| Item | PSZ100T | PSZ120T | PSZ160T | PSZ175T | |

| Mould Dimension | 1000*800 | 1200*1000 | 1600*1350 | 1750*1450 | |

| Max Product Dimension | 850*650*330 | 1050*850*330 | 1420*1200*330 | 1550*1250*330 | |

| Stroke | 210-1360mm | 210-1360mm | 270-1420mm | 270-1420mm | |

| Steam | Entry | DN65 | DN65 | DN80 | DN80 |

| Consumption | (12-15T)Steam of 1T material | ||||

| Cooling Water | Entry | DN65 | DN65 | DN65 | DN65 |

| Consumption | 45-130kg/cycle | 45-130kg/cycle | 50-140kg/cycle | 55-190kg/cycle | |

| Compressed Air | Entry | DN40 | DN40 | DN50 | DN50 |

| Consumption | 1.3m3/cycle | 1.3m3/cycle | 1.4m3/cycle | 1.5m3/cycle | |

| Vacuum Pump Capacity | 165m3/h | 165m3/h | 280m3/h | 280m3/h | |

| Power | kw | 11kw | 11kw | 16.5kw | 16.5kw |

| Overall Dimension | L*W*H (mm) | 4500*1640*2700 | 4500*1840*2900 | 5000*2300*3400 | 5000*2450

*3500 |

| Weight | kg | 4100 | 4600 | 5700 | 6000 |

| Cycle Time | s | 60-90s | 60-100s | 100-180s | 100-180s |

| Note:We can make EPP styrofoam package thermocol molding machine according to customer requirement. | |||||

Products