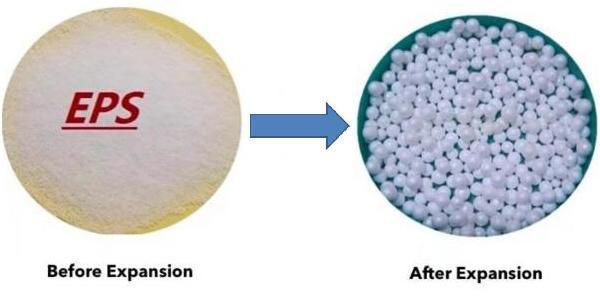

Continuous EPS Pre-Expander Machine

Main advantage

1. Fully automatic production.

2. Controlled by touch screen and PLC, easy to operate.

3. High output and save energy.

4. Exact density of foam beads.

5. Stable quality and less failure.

Main Features

1.Material weight measuring section takes special measuring controlling device and loading device,they are controlled by Touch Screen and PLC,the infeed amount can be controlled accurately,the tolerance can be the smallest(±0.05kg).

2.For the material level controlling,the machine takes vibration Induction controller Which is imported from Korea,it can feel the rising rate of the beads,keeps the Expanding density as the min. Rate(tolerance ±1% for 18-25g)

3.There is temperature controlling device in the pre-expanding vessel,it can control the temperature change into smallest level so that it can save the heat energy.

4.Steam-Water discharge device can avoid the solidification of the water and the lumping of the foam, thus it can reduce the water entrainment rate of the material.

5.When emergency accident happens (eg.power off or there are some serious problems with the machine), the steam valve can be automatically closed immediately,at the same time,the air can be infeed in the vessel automatically in case the material be lumped in the vessel.this can give double insurance for the product quality.

6.Friendly MML.Touch screen can automatically detect the default and send out alarm in order to inform the default position and repairing method,this will make maintenance more easy and quick.

7.The equipment can be operated easily.The operator can set feeding weight and other relevant parameters according to different material and their different density,and the setting can be saved freely, this can help the operator output directly during next cycle, this can improve the working efficiency as possible.

8.The heating base plate is made of high quality stainless steel and after precious laser cutting.During heating,the steam can pass through the base plate more smoothly and equivalently,this can make pre-expanding density more stable,the parcels will be more even,the steam exhaust can be reduced accordingly,this can save the material cost and the energy cost as much as possible.

Technical Data

| Item | PSY70 | PSY90 | PSY120 | |

| Expansion Chamber | Diameter | φ700mm | φ900mm | φ1200mm |

| Volume | 0.6m³ | 1.2m³ | 2.2m³ | |

| Useable Volume | 0.4m³ | 0.8m³ | 1.5m³ | |

| Steam | Entry | DN20 | DN25 | DN50 |

| Consumption | 80-100kg/h | 100-150kg/h | 150-200kg/h | |

| Pressue | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Compressed Air | Entry | DN15 | DN20 | DN20 |

| Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Drainage | Condensate | φ20mm | φ20mm | φ20mm |

| Throughput | 15g/l | 100kg/h | 150kg/h | 250kg/h |

| 20g/l | 120kg/h | 200kg/h | 300kg/h | |

| 25g/l | 150kg/h | 250kg/h | 410kg/h | |

| 30g/l | 200kg/h | 300kg/h | 500kg/h | |

| Material Conveying Line | φ150mm | φ150mm | φ150mm | |

| Power | 8.93kW | 9.73kW | 14.83kW | |

| Density | First expansion | 12-30g/l | 12-30g/l | 14-30g/l |

| Second expansion | 8-11g/l | 8-11g/l | 8-13g/l | |

| Outside Dimensions | L×W×H | 4700×2660×2600mm | 4700×2930×32000mm | 4905×4655×3250mm |

| Weight | 1300kg | 1500kg | 1800kg | |

| Room Height Required | 3000mm | 3000mm | 3000mm | |

Products

EPS products are widely used in different fields. They can be used to make eps blocks for wall and roof insulation, they can be used for packing fragile products as a cushion, or for packing fish or vegetables to keep them fresh, to make formwork for building houses, or to use only the beads for making lying bags, to mix with cement to get lightweight concrete, or to make lost foam products for making auto parts, etc.