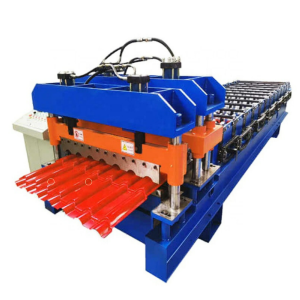

Color Steel Roof Roll Forming Machine

Product Description

Color Steel Roof Roll Forming Machine

1.This machine is made up of roll forming machine,molding press,cutting machine,PLC computer control and hydraulic system.

2.The machine is stable,no noise,no shake.

3.Controlling by computer,PLC display,operation is easy,running is steady and reliable,endurable,maintenance-free.

4.Cutting machine is characterized by stable driving,easy operation.

5.Hydraulic system use the hydraulic pump,long operating life,no noise.

Technical Data

|

Item

|

value

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Construction works , Steel Contruction

|

|

After Warranty Service

|

Video technical support, Online support

|

|

Type

|

Tile Forming Machine

|

|

Tile Type

|

Steel

|

|

Use

|

ROOF

|

|

Production Capacity

|

0-20m/min

|

|

Voltage

|

380V/50Hz/3PH,Customized

|

|

Dimension(L*W*H)

|

5800*1500*2000mm

|

|

Weight

|

2000kg

|

|

Certification

|

CE

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

Automatic

|

|

Rolling thinckness

|

0.3-0.8mm

|

|

Feeding width

|

1220mm

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Marketing Type

|

Hot Product 2022

|

|

Core Components

|

PLC

|

Main Features

Color Steel Roof Roll Forming Machine Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High precesion to control the tile length and pieces.

4) Running in a high automatization and intellectualization,no pollution

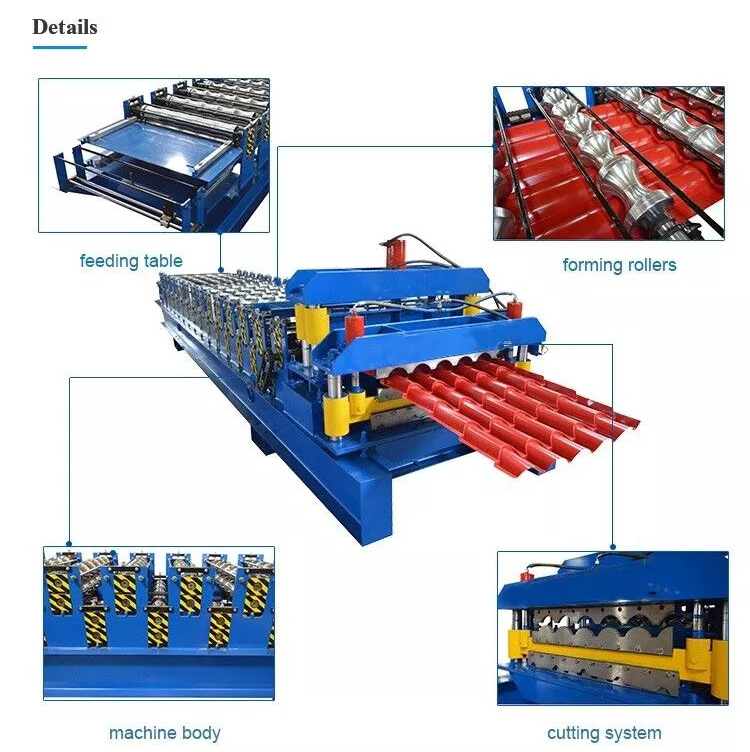

Color Steel Roof Roll Forming Machine Feeding Table

1.Features: Ensure smooth& precise material feed.

2.Components: steel plate platform, two pitching rollers, position stopping block.

3. The coil is guided in the correct position and passed to the roll forming equipment.

Color Steel Roof Roll Forming Machine Forming Rollers

1.Rollers: design by senior engineers with Auto-cad software, manufactured with 45# high grade steel by CNC machine tools and coated with hard chrome

2.Shaft:70mm manufactured with 45# high grade steel by CNC machine tools

3. Supporting frame: steel wallboard to guide the forming station bearing basement

4.The finished products will change if using different material and thickness

5.Driving of machine:by one inch chain

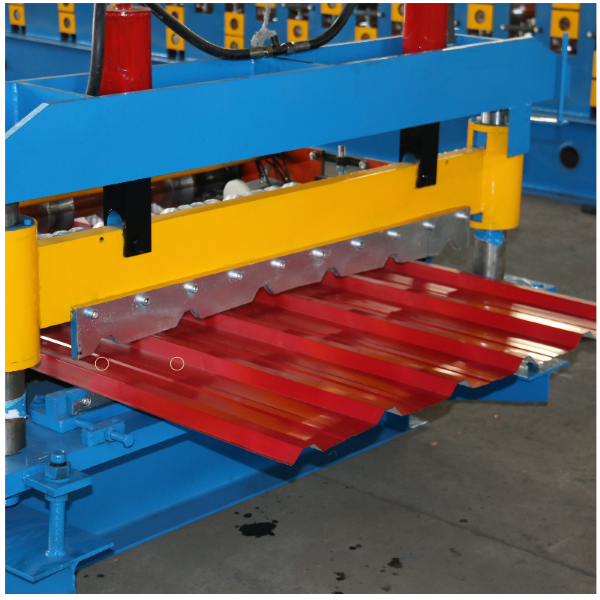

Color Steel Roof Roll Forming Machine Cutting System

1.Function: cutting action is controlled by PLC. The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

2.Power supply: hydraulic station

3.Frame: welding steel frame

4.Stroke switch: non-contact photoelectric switch

5.Cutting before forming: cut the sheet after roll forming to required length

6.Length measuring: automatic length measuring

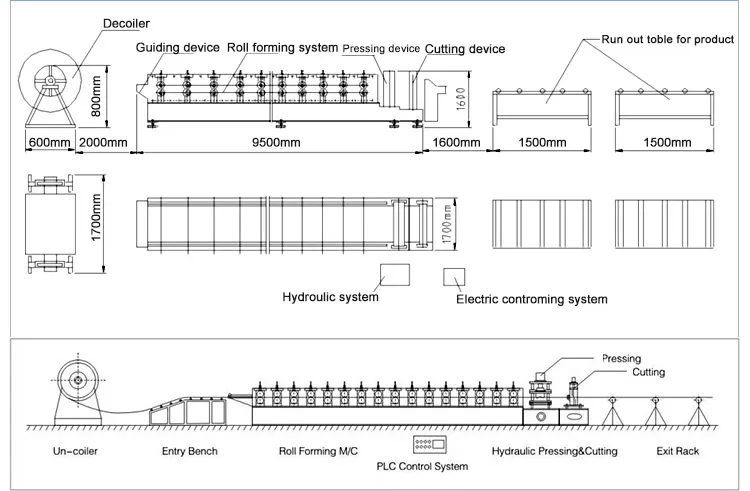

Producing Process

Material supporting frame→Molding core→Hydraulic system→Automatic control system→Automatic shearing mechanism→Roll forming receiving tables

Application

Color Steel Roof Roll Forming Machine is widely used in the construction of various industrial plants, villages, warehouses, supermarkets, hotels, exhibition, family construction, shopping malls shutter doors and etc. It has the advantage of beautiful, classical appearance and grace taste.

Packing & Shipping

1. Need one 40ft container.

2. Fit for ocean shipping.

3. The main body of the roll forming machine will be naked packing into the container, covered with plastic film.

4. Steel wire fixes the machine into the container, in case of any damage when shaking on the sea.

5. The spare parts will be packed into the carton box.

6. The received goods table put into carton box.

7. Manual decoiler naked package.