Best Selling PSB200TZ-600TZ Auto EPS Vaccum Insulation Panel Making Machine

Main Features

1. EPS block moulding machine is made of high strength pipe and steel plate, all the steel is under heat treatment, sand blasting, spraying antirust painting, to increasing strength, not rust, to ensure machine operation is stable and long service life.

2. EPS block moulding machine adopts advanced processing technology and better pipe structure design, greatly improving the production efficiency.

3.Adopt unique EPS through heating molding process and efficient vacuum and condensing unit, has a strong penetrating power, excellent bondability,cooling speed ,low moisture content,excellent product quality ,remarkable energy saving.

4.Adopt PLC and touch screen control system , equipped with material level sensor can realize automatic control of feeding ,equipped with foam pressure sensor control cooling time automatically.

5.Machine use good quality electrical ,pneumatic components,valves and other parts. And the parts with intrnational standard, so customer is easy to find replacement at local.

6.Machine adopts hydraulic pressure station to be the center conteol system.Use hydraulic open door,ejector de-mould and locking ,guarantee the machine running smoothly,stable performance.

7.The machine can be designed height or width adjused.TO reduce waste of material ,in order to save costs and increase profit.

Technical Data

| Item | Type | ||||

| PSB200TZ | PSB300TZ | PSB400TZ | PSB600TZ | ||

| Mould Cavity Size | mm | 2050*1240-940*1030 | 3060*1240-940*1030 | 4080*1240-940*1030 | 6100*1240-949*1030 |

| Block Size | mm | 2000*1200-900*1000 | 3000*1200-900*1000 | 4000*1200-900*1000 | 6000*1200-900*1000 |

| Steam | Entry | DN150 | DN150 | DN150 | DN200 |

| Consumption | 25-45kg/cycle | 45-65kg/cycle | 60-85kg/cycle | 95-120kg/cycle | |

| Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Compressed Air | Entry | DN40 | DN40 | DN50 | DN65 |

| Consumption | 1.5-2m3/cycle | 1.8-2.2m3/cycle | 2-2.5m3/cycle | 2-3m3/cycle | |

| Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | |

| Cooling Water | Entry | DN40 | DN40 | DN40 | DN40 |

| Consumption | 0.2-0.4m3/cycle | 0.4-0.6m3/cycle | 0.6-0.8m3/cycle | 0.8-1m3/cycle | |

| Pressure | 0.4-0.6MPa | 0.4-0.6MPa | 0.4-0.6MPa | 0.4-0.6MPa | |

| Drainage | Vacuum drain | Φ100mm | Φ125mm | Φ125mm | Φ125mm |

| Steam vent | Φ100mm | Φ100mm | Φ200mm | Φ200mm | |

| Condensate | Φ150mm | Φ150mm | Φ150mm | Φ150mm | |

| Blower outlet | Φ100mm | Φ100mm | Φ150mm | Φ150mm | |

| Throughput | 15kg/m3 | 4min/cycle | 6min/cycle | 7min/cycle | 8min/cycle |

| Power | 23.75Kw | 26.75Kw | 28.5Kw | 37.5Kw | |

| Overall Dimension | L*W*H | 5700*4000*3300 | 7200*4500*3500 | 11000*4500*3500 | 12600*4500*3500 |

| Weight | 8000kg | 9500kg | 15000kg | 18000kg | |

| Room Height Required | 6000mm | 6000mm | 6000mm | 6000mm | |

Case

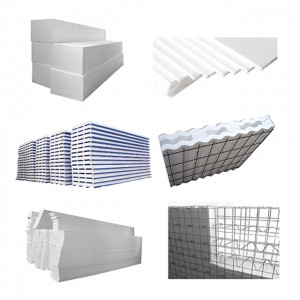

EPS Foam Blocks for Waterproof Road Construction

3D panel house building