Automatic EPP Moulding Machine

product description

Expanded Polypropylene (EPP) is a highly versatile closed-cell bead foam that provides a unique range of properties, including outstanding energy absorption, multiple impact resistance, thermal insulation, buoyancy, water and chemical resistance, exceptionally high strength to weight ratio and 100% recyclability.

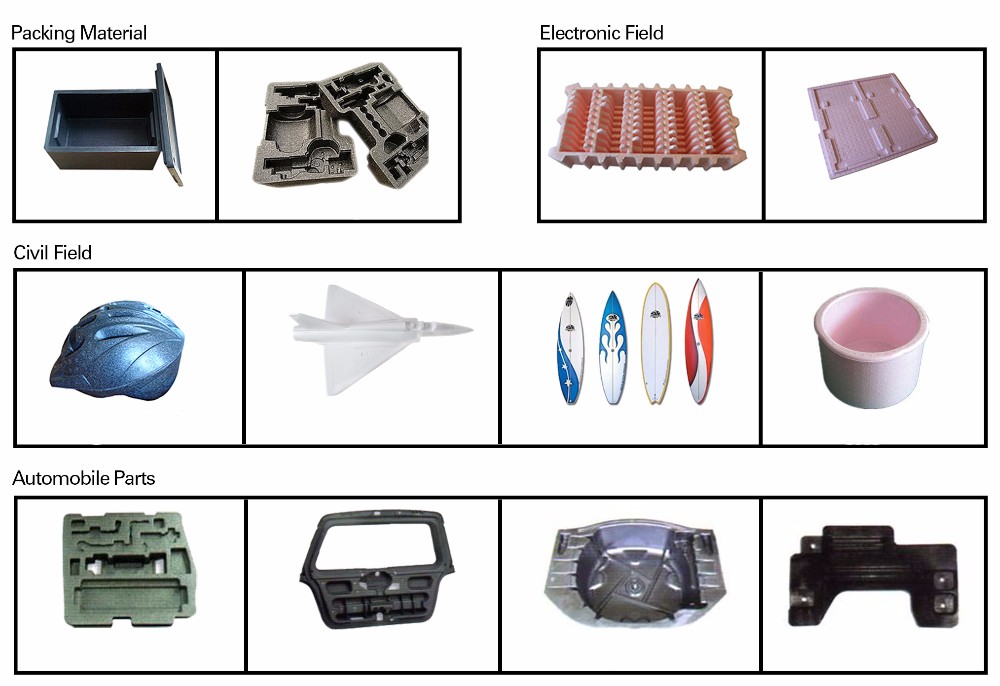

Automatic EPP Moulding Machine is used to produce all kinds of valuables EPP packaging (such as notebook computers, liquid crystal displays, precision instruments), EPP toys (airplane models), EPP high-end car parts (such as EPP bumper, EPP toolbox, EPP sunshade, etc.), EPP sporting goods (such as Surfboard, helmet, etc.).

Main Features

1. Use proportional steam valve for save steam and heat accurately.

2. Can install the filling guns and ejectors on the ground, can save time to install moulds.

3. Special designed hopper can control the material filling more accurately to ensure make good quality products.

4. Use stainless steel oil pipes to keep machine running stable and not leak oil.

5. Lock moulds same as Germany machine, can keep high pressure in the moulds.

6. All pipe and mould plate coated with zinc, to ensure the machine not easy to get rust and long time running with the steam and water.

Technical Data

| Item | PSZS-1412 | PSZS-1816 | PSZS-2018 | ||

| Mould Dimension | mm | 1400*1200 | 1850*1600 | 2000*1800 | |

| Rear window dimensions | mm | 1250*1050 | 1700*1450 | 1750*1650 | |

| Effective forming area | mm | 1200*1000 | 1500*1250 | 1650*1450 | |

| Max Produce Size | mm | 400 | 400 | 400 | |

| Steam | Pipe connect | DN | 100 | 100 | 100 |

| Die connect | DN | 40/6 | 40/8 | 40/8 | |

| Pressure | kg/cm² | <5 | <5 | <5 | |

| Consumption | kg/cycle | 3-12 | 3-15 | 3-18 | |

| Air | Pipe connect | DN | 80/2 | 80/2 | 80/4 |

| Pressure | kg/cm² | <4 | <4 | <4 | |

| Cooling Water | Pipe connect | DN | 80 | 80 | 80 |

| Die connect | DN | 25/2 | 25/3 | 25/3 | |

| Pressure | kg/cm² | <3 | <3 | <3 | |

| temperature | ℃ | 45-55 | 45-55 | 45-55 | |

| Single Vacuum | Motor | KW | 5 | 7.5 | 7.5 |

| Connect | DN | 100 | 100 | 100 | |

| Drain | DN | 40 | 40 | 40 | |

| Dain water | DN | 25 | 25 | 25 | |

| Vacuum Center | Connect | DN | 100 | 100 | 100 |

| Drainage | Drain Outlet | Φ | 159 | 159 | 159 |

| Mould Outlet | DN | 40/3 | 40/4 | 40/4 | |

| Hydralic system | Motor | KW | 7.5 | 11 | 11 |

| Pump | L/min | 31/97 | 31/116 | 31/116 | |

| Lock power | T | 24 | 37 | 46 | |

| Open-close cylinder | mm | 100*2 | 125*2 | 140*2 | |

| Demould cylinder | mm | 50*2 | 50*2 | 50*2 | |

| Hopper | Volume | m³ | 0.3 | 0.4 | 0.4 |

| Motor | KW | 1.5 | 2.2 | 2.2 | |

| Material hole | Pieces | 22 | 44 | 44 | |

| Electric Load | KW | 16.5 | 20.7 | 20.7 | |

| Overall Dimension | mm | 4800*3320*2800 | 4800*3600*3200 | ||

| Weight | kg | 7200 | 8000 | ||

Our Service

1.Value clients, guarantee equipment quality and answer clients' questions anytime and anywhere.

2.Customizing machines according to clients' inquiry , such as different design, different brand parts, different colors, more function,etc.

3.Engineers go to clients' factory in time for installation , training and trial production .

4. More spare parts are given to clients for free to ensure the factory working without suddenly stop.

5. 1 year free warranty, Lifetime technical service support.

Product